Ballistic And Bullet Protection / Resistant Products

Ballistic and Bullet Test Standards And Methodology

Ballistic Test Standards and Methodology

Below is a comprehensive and technical list of widely-recognized ballistic testing standards used in Europe, the United States, NATO/military contexts, and other regions, together with detailed explanations of how each test method is carried out.

European Ballistic Standards (Architectural Applications)

Europe uses harmonised standards developed by the European Committee for Standardization (CEN) for evaluating the ballistic resistance of both glazing (transparent elements) and complete assemblies (windows, doors, shutters, blinds, louvres). These standards are widely adopted by testing laboratories throughout EU/EEA and referenced in UK national implementations (BS EN).

EN 1063 – Glass in Building – Security Glazing – Testing and Classification of Resistance Against Bullet Attack

Scope & Purpose:

EN 1063 states the performance requirements and testing methods specifically for bullet-resistant glazing (glass and glass-plastic laminate composites) intended to protect against handguns and rifles also with regard to a wide range of ammunition. It applies to glazing products for buildings, designed to resist penetration by bullets under controlled conditions. See below for testing criteria.

Classification:

Glass is classified into ballistic classes BR1 to BR7, plus shotgun classes SG1/SG2. Each class corresponds to a specific weapon calibre, type and projectile velocity. For example:

o BR2 – 9 mm Luger threat

o BR5 – 5.56 × 45 mm NATO rifle

o BR6 – 7.62 × 51 mm NATO rifle

o BR7 – 7.62 × 51 mm AP (armour-piercing) rifle

Test Setup

o Specimen size is typically in the region of 500 mm × 500 mm mounted rigidly in a test fixture.

o The test specimen includes only the glazing itself (glass/polymer layers) without the full frame.

o The firing distance is generally 5 m or 10 m depending on class.

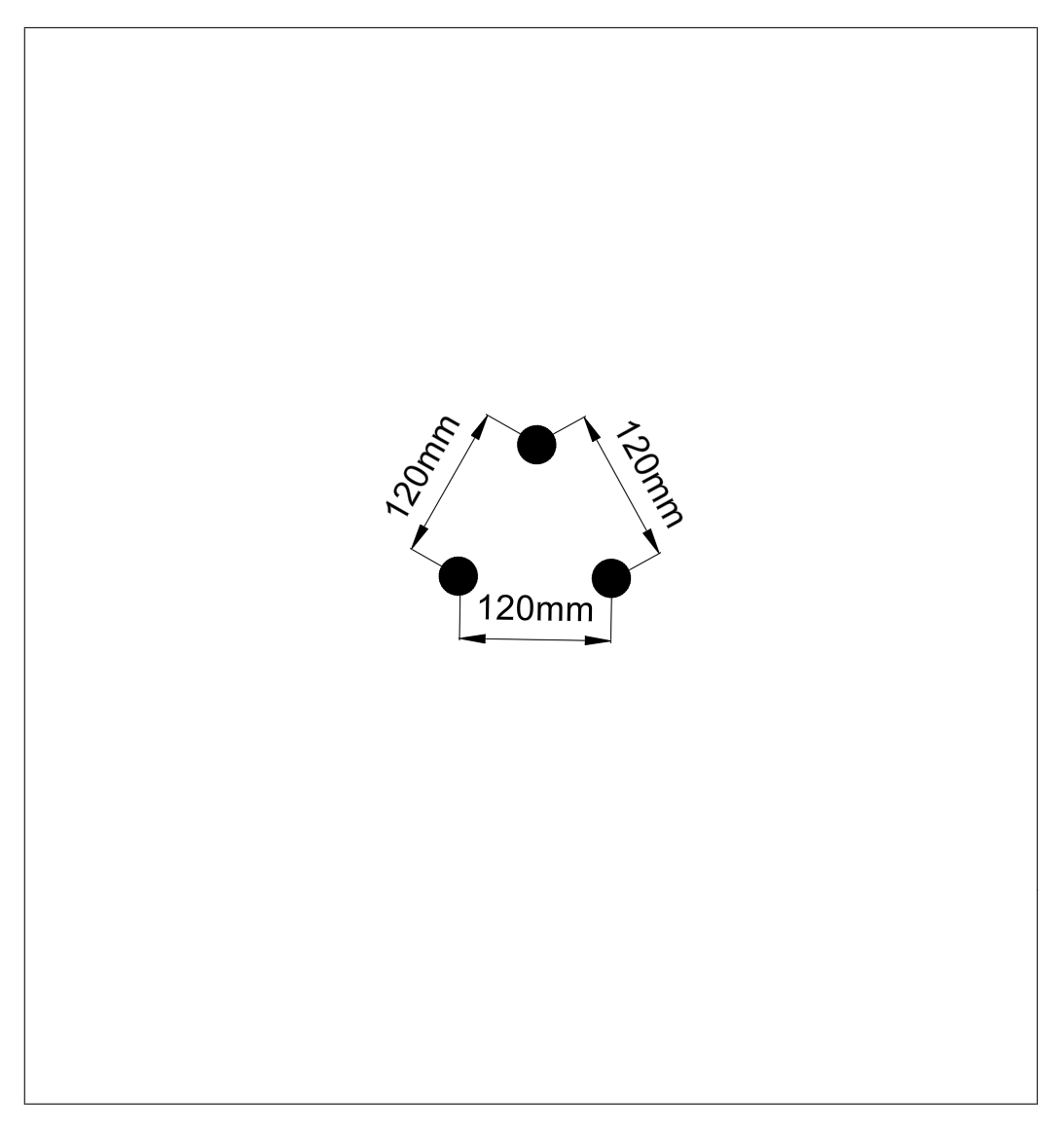

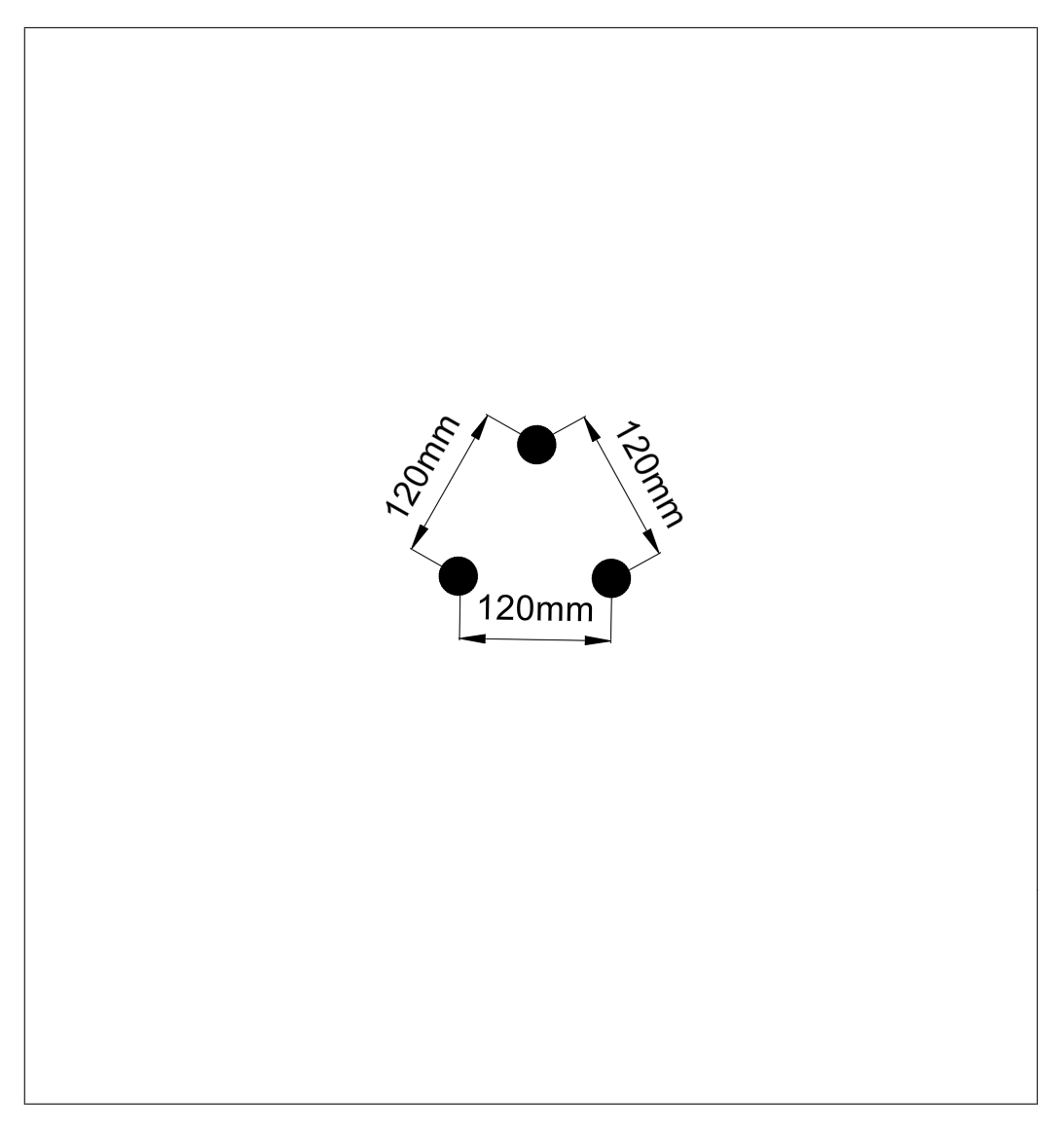

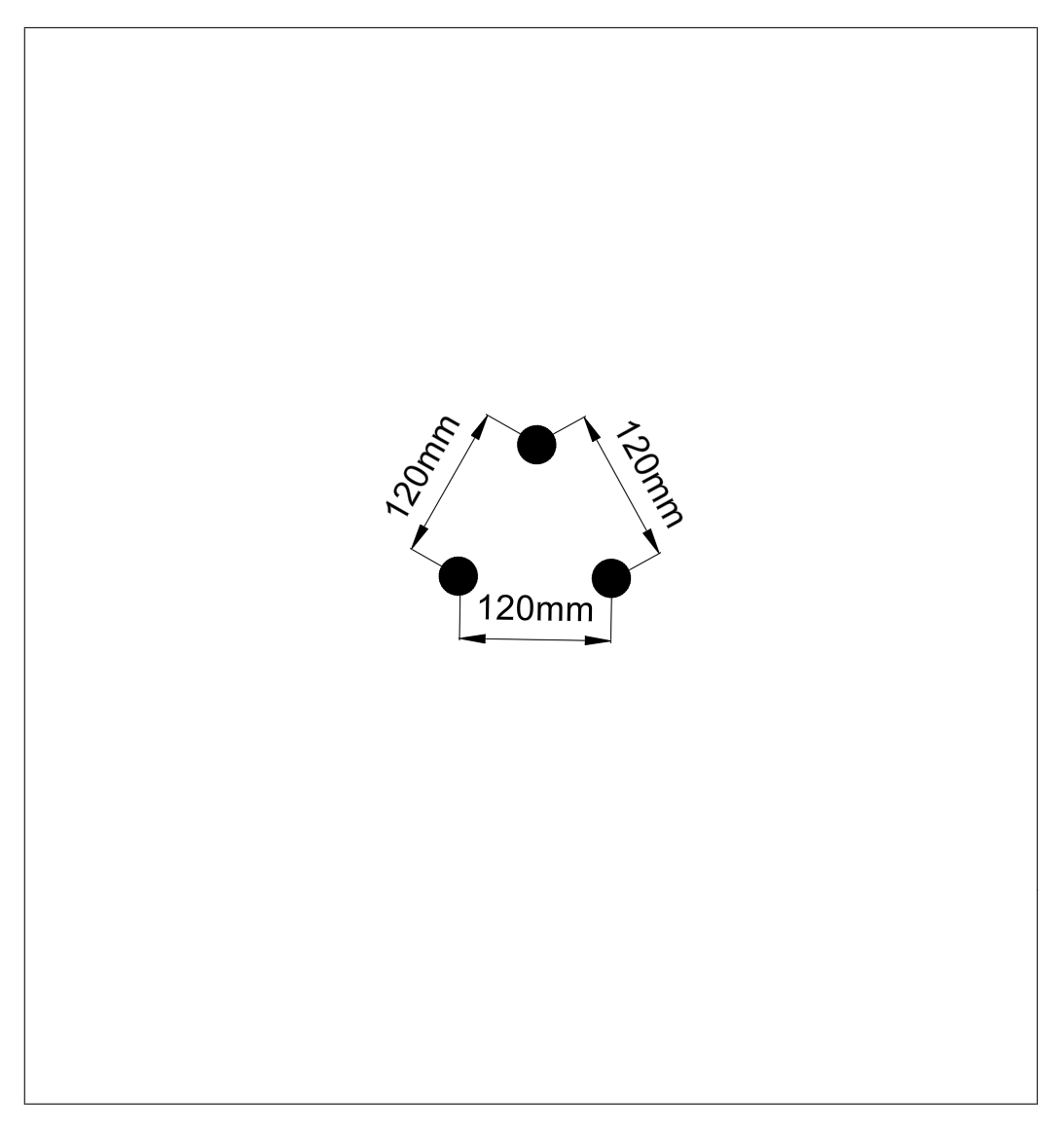

o Projectile impact points are arranged in a triangular pattern (three shots) spaced approximately 120 mm apart and perpendicular to the specimen surface.

Procedure:

1. Pre-inspection & Documentation: Measure dimensions, prepare identification marks for impact locations.

2. Mounting: Secure the glazing in a rigid frame to ensure repeatable boundary conditions.

3. Ballistic Firing: Fire three rounds from a defined firearm type/munition at a controlled velocity. Impact points are spaced in a triangular geometry (120 mm minimum centre-to-centre). The angle of attack typically is 90° (normal to surface).

4. Evaluation:

o Pass requires no complete penetration of any test projectile.

o Additional “NS” (No Spall) notation may be awarded if no fragments exit the protected face of the glazing.

o S (Spall Allowed) is recorded if fragments exit.

o Measure residual effects (e.g., back face cracking) and document.

5. Acceptance: Report projectile velocities, impact pattern, penetration/no-penetration, and spall status for classification.

Simplified Test Geometry Diagram:

Notes:

EN 1063 tests glazing as separate selements and must be must also be installed into framework or similar (EN 1522/1523) to provide a complete product as the integration between glass and framework combine to form a system.

Glazing thickness and composition (glass + polycarbonate interlayers) directly influence resistance level.

EN 1522 / EN 1523 – Bullet Resistance of Windows, Doors, Shutters, Louvres & Blinds Standards:

o EN 1522: Requirements and classification

o EN 1523: Test method

Scope & Purpose:

These standards define requirements and a repeatable ballistic test method for complete architectural assemblies — including windows, doors, shutters, louvres and blinds — with all structural elements included (frames, seals, fixings, hardware). Their purpose is to verify that a complete installed unit resists defined ballistic threats without penetration or unacceptable failure.

Classification:

Bullet resistance classes defined as FB1 to FB7:

o FB1: .22 LR

o FB2: 9 mm

o FB3: .357 Magnum

o FB4: .44 Magnum

o FB5: 5.56 × 45 mm

o FB6: 7.62 × 51 mm

o FB7: 7.62 × 51 mm AP (armour-piercing)

Test Setup

o The Complete assembly is mounted in a test frame simulating the installation conditions (including fixings to wall).

o Critical vulnerable areas are identified:

- Glass panel(s)

- Frame members around edges

- Joints, seals and hinges/lock areas

o The firing distance and ammunition are specified per class.

Procedure

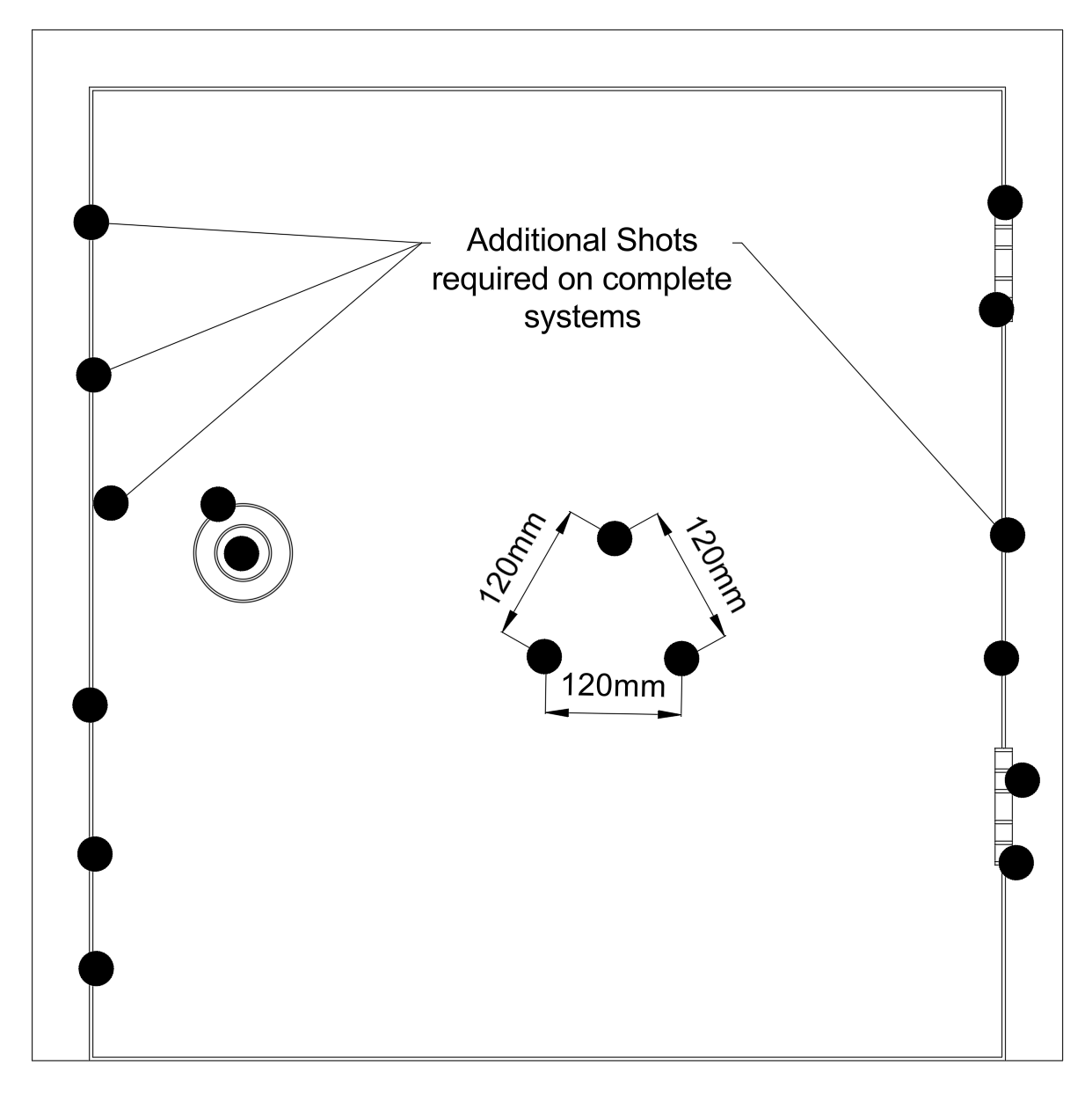

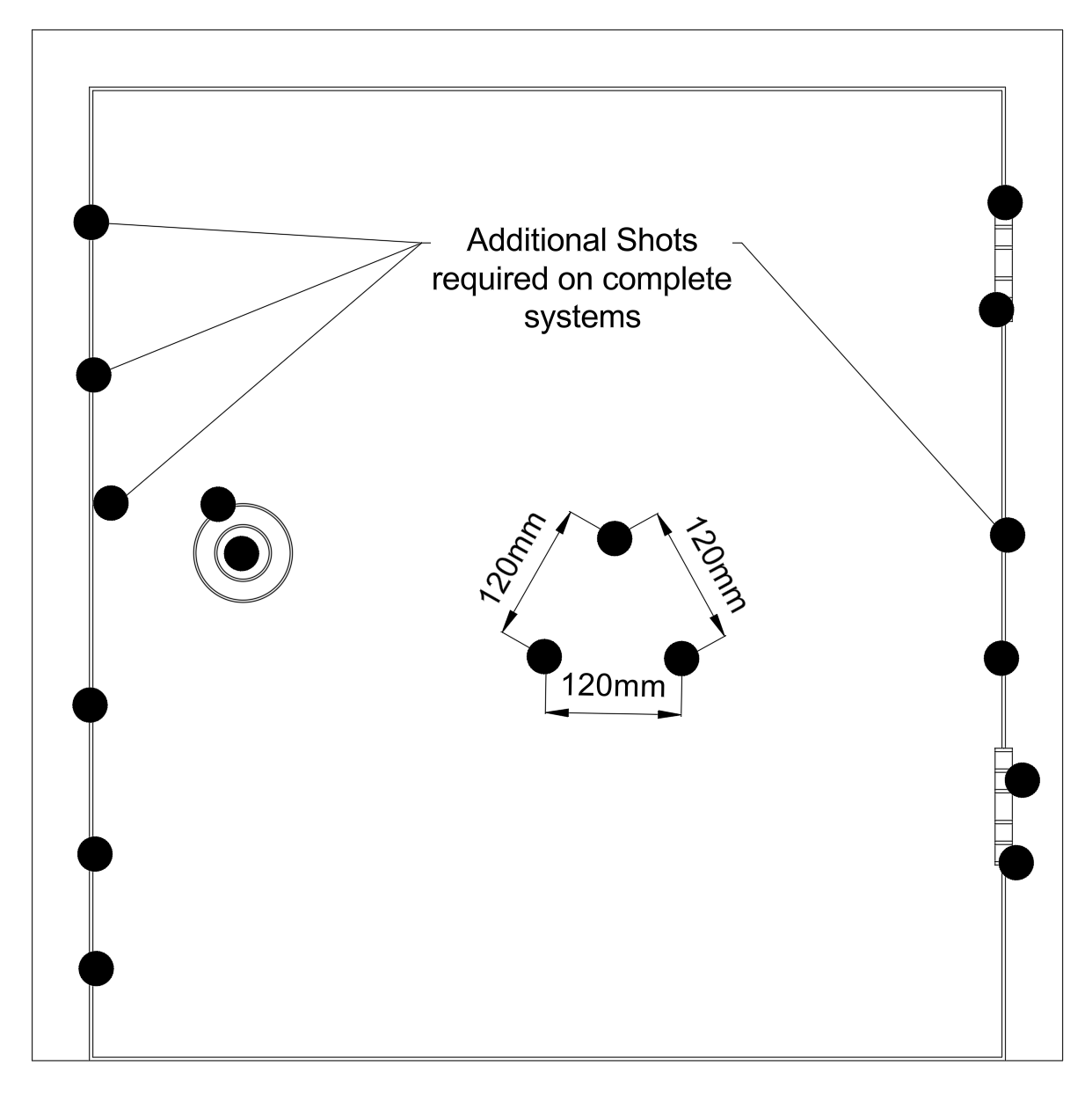

1. Risk Analysis & Shot Plan: Evaluate assembly to identify potential weak points and create a shot matrix covering infill and frame vulnerabilities.

2. Firing: Fire the required number of shots at each location defined in test plan. Shots are directed to produce the worst credible damage (angles may vary slightly to stress hardware).

3. Evaluation: Pass requires no projectile perforation through the assembly and assess excessive deformation, joint failure, glass/rim splits, hinge/lock compromise.

4. Documentation: Record site-specific details, shot sequence, velocities, observed failures and assign an FB classification.

Window / Door Front View - Shot Distribution Diagram:

Key Differences from EN 1063

o EN 1522/1523 tests the entire assembly, not only the glass.

o Tests incorporate structural fixings and hardware behaviour under ballistic loads.

o Classification levels FB1–FB7 align with glazing BR1–BR7 but include assembly performance.

BS 5051 – Historic UK Standard for Bullet-Resistant Glazing

The standard described is BS 5051, specifically BS 5051-1:1988 for interior use and BS 5051-2:1987 for exterior use.

While largely superseded by the European standard BS EN 1063, BS 5051 remains relevant in legacy specifications and is still frequently referenced by UK manufacturers for its specific classifications:

o Handgun Resistance: Classified into levels G0, G1, and G2.

o Rifle Resistance: Classified into levels R1 and R2 (and sometimes R2ap for armor-piercing).

o Shotgun Resistance: Specifically designated as level S86.

Key differences between this legacy standard and the current BS EN 1063 include:

o Scope: BS 5051 focuses strictly on the ballistic resistance of the glass itself, whereas newer standards (such as EN 1522/1523) also incorporate the testing of frames and mounting systems.

o Classifications: BS EN 1063 uses BR1–BR7 for small arms and SG1–SG2 for shotguns, replacing the G, R, and S alphanumeric codes used in BS 5051.

North American Ballistic Standards (Architectural)

In the United States, multiple standards are used for testing ballistic resistance of glazing, panels, doors, louvers and assemblies. The two most common are UL 752 and ASTM F1233, with NIJ 0108.01 sometimes referenced.

UL 752 – Standard for Bullet-Resisting Equipment

Scope & Purpose

UL 752, published by Underwriters Laboratories (UL Solutions), specifies test methods and performance levels for materials, devices, assemblies, and fixtures used as bullet-resisting barriers, including glazing, wall panels, louvres and doors. The standard ensures prevention of complete projectile penetration and harmful spall.

Classification

UL 752 defines multiple performance levels, commonly numbered 1 through 8 (and extended levels). Each level corresponds to specific bullet calibres, ammunition types, number of shots and impact velocities. Examples:

o Level 1: 9 mm handgun, 3 shots

o Level 3: .44 Magnum, 3 shots

o Level 5–8: Rifle threats (5 shots) including 5.56 mm and 7.62 mm at defined velocities.

Test Setup

o Test specimen may be individual panel or a full assembly.

o The fixture is designed to simulate real installation conditions.

o Coordinate system for shot grouping defined per level.

Procedure

1. Conditioning: Specimen is prepared and conditioned per standard environmental requirements.

2. Weapons & Ammunition: Use specified firearms, ammunition and grain weights aligned to each level.

3. Fire Testing: Shots are fired at the specimen from specified distances (e.g., ~4.6 m). Group formations and velocities are regulated for consistency.

4. Acceptance Criteria:

o No complete penetration at any tested point.

o No hazardous spall on the protected side.

o Fail criteria include penetration or hazardous fragmentation.

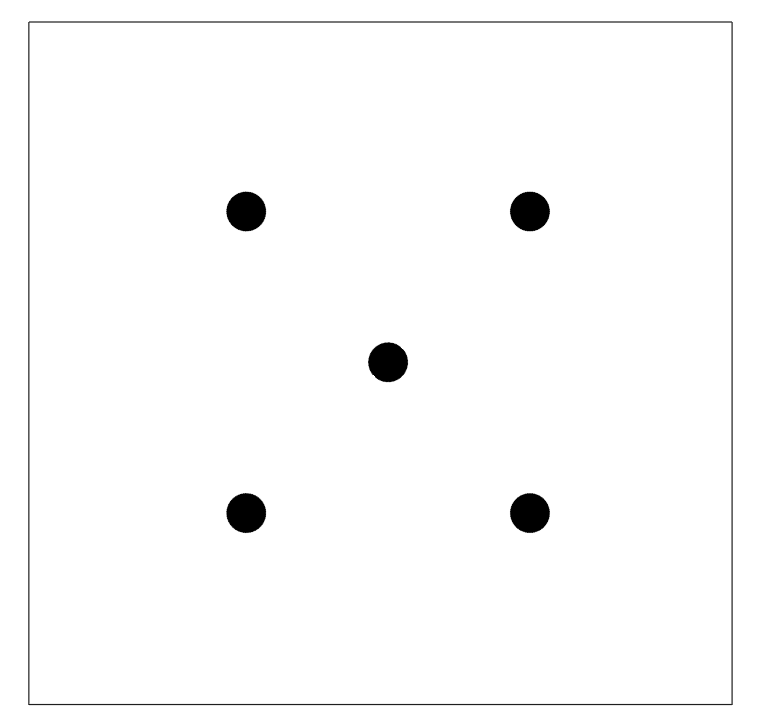

Diagram of UL 752 and

NIJ 0108.01

Shot Group:

Notes

o UL 752 tests both opaque panels and glazing products (or assemblies that incorporate both).

o Results are used in building specifications for banks, government facilities, schools and so forth

ASTM F1233 – Standard Test Method for Security Glazing Materials and Systems

Scope & Purpose

ASTM F1233

is a forced-entry resistance test that integrates ballistic resistance within a broader forced-entry context. It provides a series of performance classes that include ballistic threat levels and forced-entry testing for glazing systems and assemblies.

Classification

Eleven classes describe levels of resistance including one to three shots from defined calibres (e.g., .38 cal, .308 Win, .30-06 AP). Specifications classify

both ballistic and forced-entry (tool) resistance.

Procedure

1. Ballistic firing as with UL 752/NIJ (defined calibres, distances and velocities).

2. Forced entry tool assault simulating manual attack tools.

3. Criteria require no penetration (ballistic) and resistance to tool attack for defined time.

Notes

ASTM F1233 is widely used for glazing systems where both forced-entry and ballistic resistance are required in integrated façade security specifications.

Additional / Regional Standards & Comparators

NIJ 0108.01 – US NIJ Ballistic Resistant Materials

A U.S. National Institute of Justice standard sometimes used to rate ballistic resistant materials (including glass and panels), though it originated from body armour materials and is less frequently specified for building systems than UL 752 and ASTM F1233.

GOST R50963-96 – Russian Ballistic Standard

Referenced in some comparative tables; provides ballistic resistance classifications for materials and barriers using Soviet-era calibres.

Shotgun Test Classes (SG1/SG2)

Some standards (EN 1063) include shotgun impacts as part of classification (SG1/SG2), reflecting threats from large-bore shotguns.

Comparative Table of Standards

| Standard | Scope | Threat Basis | Classification Units | Key Outcome |

|---|---|---|---|---|

| EN 1063 | Ballistic glazing | Bullets, shotguns | BR1 - BR7, SG1 / SG2 | No penetration plus spall status |

| EN 1522/1523 | Complete windows / doors | Bullets, shotguns | FB1 - FB7 (+FSG) | No penetration (structural) |

| UL752 | Bullet-resisting equipment and assemblies | Handguns and riflles | Level 1 - 8 + | No penetration plus no dangerous spall |

| ASTM F1233 | Security glazing and forced entry | Bullets and tools | 11 classes | Combined ballistic and tool resistance |

| NIJ 0108.01 | Ballistic resistant materials | Defined calibres | NIJ levels | No perforation |

Key Technical Considerations for Testing

Instrumentation & Setup

o Chronographs for precise velocity measurement.

o Rigid mounting fixtures replicating installed boundary conditions.

o High-speed cameras for impact and fracture analysis.

Environmental Conditioning

o Temperature and humidity per standard conditions prior to ballistic tests.

Data Recording

o Projectile velocities, impact coordinates, penetration status, spall, and deformation.

Acceptance Criteria

o No complete penetration through resistant face.

o Control of spall or fragment exit as specified for standard (e.g., NS/SA in EN 1063, no hazardous spall in UL).

Below are numerical firing tables with detailed weapon and ammunition definitions per ballistic class for the principal architectural ballistic resistance standards used in Europe and North America. These tables cite standardized calibres, bullet types, masses, velocities, test distances, and number of shots for glazing and full assembly testing.

EN 1063 – European Ballistic Glazing Standard

EN 1063 specifies ballistic resistance classes BR1–BR7 and SG1/SG2 for security glazing. Each class has defined test ammunition, shot count, test range, and reference impact velocities. The glazing sample size is around 500 mm × 500 mm with shots fired in an equilateral triangular pattern at 120 mm ± 10 mm spacing (typically 3 shots, except SG1).

EN 1063 Firing Parameters:

| Class | Weapon Type | Calibre | Bullet Type | Mass (g) | Velocity (m/s) | Energy (J) | Range (m) | Shots |

|---|---|---|---|---|---|---|---|---|

| BR1 | .22 LR | .22 LR | Lead RN | 2.6 | 360 +/- 10 | ~168 | 10 | 3 |

| BR2 | Handgun | 9 x 19mm Luger | Full Jacket / RN / Soft Core | 8.0 | 400 +/- 10 | ~640 | 5 | 3 |

| BR3 | Handgun | .357 Magnum | Full Jacket / Conical / Soft Core | 10.2 | 430 +/- 10 | ~940 | 5 | 3 |

| BR4 | Handgun | .44 Rem Magnum | Full Jacket / Flat Nose / Soft Core | 15.6 | 440 +/- 10 | ~1,510 | 5 | 3 |

| BR5 | Rifle | 5.56 x 45mm NATO | Full Jacket / Pointed Soft Core / SS109 | 4.0 | 950 +/- 10 | ~1,805 | 10 | 3 |

| BR6 | Rifle | 7.62 x 51mm NATO | Full Jacket / Pointed Soft Core | 9.5 | 830 +/- 10 | ~3,272 | 10 | 3 |

| BR7 | Rifle (AP) | 7.62 x 51mm NATO | Full Jacket / Pointed Hard Core | 9.8 | 820 +/- 10 | ~3,295 | 10 | 3 |

| SG1 | Shotgun | 12 Guage (70mm) | Solid Lead Slug | 31 | 420 +/- 20 | ~2,734 | 10 | 1 |

| SG1 | Shotgun | 12 Gua | Solid Lead Slug | 31 | 420 +/- 20 | ~2,734 | 10 | 3 |

Notes

o RN = Round Nose; FN = Flat Nose; PB = Pointed Bullet; SC = Soft Core; HC = Hard Core (steel, >63 HRC).

o Shot pattern and exact sample conditioning follow the method described in EN 1063.

EN 1522 – European Ballistic Resistance for Windows/Doors/Louvres

EN 1522 classes FB1–FB7 align with EN 1063 ballistic classes and use the same ammunition definitions above. Test distance and velocities are identical to EN 1063 for corresponding classes; the difference is that complete assemblies (including frames, seals, hinges) are tested rather than glazing alone.

For example:

| EN 1522 Class | Equivalent EN 1063 Class | Calibre | Velocity (m/s) | Shots | Range (m) |

|---|---|---|---|---|---|

| FB1 | BR1 | .22 LR | 360 +/- 10 | 3 | 10 |

| FB2 | BR2 | 9 x 19mm Luger | 400 +/- 10 | 3 | 5 |

| FB3 | BR3 | .357 Magnum | 430 +/- 10 | 3 | 5 |

| FB4 | BR4 | .44 Magnum | 440 +/- 10 | 3 | 5 |

| FB5 | BR5 | 5.56 x 45mm | 950 +/- 10 | 3 | 10 |

| FB6 | BR6 | 7.62 x 51mm | 830 +/- 10 | 3 | 10 |

| FB7 | BR7 | 7.62 x 51mm AP | 820 +/- 10 | 3 | 10 |

UL 752 – North American Ballistic Standard

UL 752 defines ballistic resistance Levels 1–8 (and higher). It is widely referenced for glazing, wall panels, doors, louvers and complete bullet-resisting assemblies in North America. Each level defines specific rounds, number of shots, and required impact velocities.

UL 752 Ballistic Levels

| UL Level | Ammunition | Calibre | Bullet Type / Weight | Velocity (ft/s/kfps) | Shots |

|---|---|---|---|---|---|

| Level 1 | 9mm FMJ | 9 x 19mm | Full Metal Jacket, Lead Core (124 gr) | 1,175 - 1,295 ft/s | 3 |

| Level 2 | .357 Magnum | .357 Mag | Jacketed Lead Soft Point (158 gr) | 1,250 - 1,375 ft/s | 3 |

| Level 3 | .44 Magnum | .44 Mag | Lead Semi-Wadcutter (240 gr) | 1,350 - 1,485 ft/s | 3 |

| Level 4 | .30-06 Rifle | .30-06 | Soft Point (180 gr) | 2,450 - 2,794 ft/s | 1 |

| Level 5 | 7.62 x 51mm | .308 | Military Ball FMJ (150 gr) | 2,750 - 3,025 ft/s | 1 |

| Level 6 | 9mm FMJ | 9 x 19mm | FMJ, Lead Core (124 gr) | 1,400 - 1,540 ft/s | 5 |

| Level 7 | 5.56 x 45mm | .223 | FMJ, Lead Core (55 gr) | 3,080 - 3,388 ft/s | 5 |

| Level 8 | 7.62 x 51mm | .308 | FMJ, Lead Core (150 gr) | 2,750 - 3,025 ft/s | 5 |

Notes

o Velocities are published as feet per second (ft/s); conversion to m/s available upon request.

o Levels beyond 8 may include .30-06 AP, .50 calibre, or shotgun threats depending on UL updates and specific product certifications.

o Pass criteria include no projectile penetration and no hazardous spall.

NIJ 0108.01 Ballistic Levels

| UL Level | Ammunition | Calibre | Bullet Type / Weight | Velocity (m/s) | Velocity (ft/s) | Shots |

|---|---|---|---|---|---|---|

| Level I | .22 Long Rifle HV | .22 LR | Lead Round Nose, 40 gr (2.6g) | 320 +/- 12 | 1,050 +/- 40 | 5 |

| Level I | .38 Special | .38 Spl | Lead Round Nose, 158 gr (10.2g) | 259 +/- 15 | 850 +/- 50 | 5 |

| Level IIA | 9mm Parabellum | 9 x 19mm | FMJ, 124 gr (8.0g) | 332 +/- 12 | 1,090 +/- 40 | 5 |

| Level IIA | .357 Magnum | .357 Mag | Jacketed Soft Point, 158 gr (10.2g) | 381 +/- 15 | 1,250 +/- 50 | 5 |

| Level II | 9mm Parabellum | 9 x 19mm | FMJ, 124 gr (8.0g) | 358 +/- 12 | 1,175 +/-40 | 5 |

| Level II | .357 Magnum | .357 Mag | Jacketed Soft Point, 158 gr (10.2g) | 425 +/- 15 | 1,395 +/- 50 | 5 |

| Level IIIA | 9mm Parabellum | 9 x 19mm | FMJ, 124 gr (8.0g) | 426 +/- 15 | 1,400 +/- 50 | 5 |

| Level IIIA | .44 Magnum | .44 Mag | Lead SWC GC, 240 gr (15.55g) | 426 +/- 15 | 1,400 +/- 50 | 5 |

| Level III | 7.62mm NATO | 7.62 x 51mm | FMJ, 150 gr (9.7g) | 838 +/- 15 | 2,750 +/- 50 | 5 |

| Level IV | .30-06 Sprinfield AP | .30-06 | Armor / Armour-Piercing, 166gr (10.8g) | 868 +/- 15 | 2,850 +/- 50 | 1 |

ASTM F1233 – Security Glazing and Systems (Ballistic + Forced Entry)

ASTM F1233 includes ballistic testing within a broader forced-entry evaluation. While it does not publish a simple table in the standard text freely online, industry references confirm that up to 12 ballistic classes exist, often aligned with UL 752 in calibre and shot count requirements.

A representative, ballistic component of ASTM F1233 uses weapons similar to UL 752 but typically with 1–3 shots per test round and may be integrated with subsequent forced-entry tool attack sequences.

Example Diagrams (Engineering-Ready)

Below are schematic diagrams appropriate for inclusion in technical documentation. These can be recreated in CAD based on provided dimensions and impact coordinates.

Figure 1: EN 1063 Shot Pattern for BR1–BR7

Figure 2 — UL 752 and NIJ 0108.01 Shot Grouping (Level-Dependent)

Ammunition Definitions

| Term | Meaning |

|---|---|

| FMJ | Full Metal Jacket - bullet encased in harder metal jacket |

| Soft Core (SC) | Lead or softer material core beneath jacket |

| Hard Core (HC) | Steel or hardened metal core for penetration (AP) |

| RN | Round Nose projectile |

| FN | Flat Nose projectile |

| Pointed (PB) | Projectile with tapering nose profile |

| SS109 / SCP1 | Military 5.56 x 45mm penetrator type |

Notes on Usage

o EN 1063/EN 1522: European test velocities are specified with tolerances (±10 m/s) and shot distances vary by class (5 m for pistol threats, 10 m for rifle/shotgun).

o UL 752: Shot patterns and impact grouping tolerances are defined within the Standard; overall barrier passes when no bullet or firearm can penetrate to allow muzzle entry.

o ASTM F1233: Combines ballistic and physical attack sequences; ballistic classes often reference handgun/rifle calibres similar to UL 752.

EN 1063 / EN 1522 — Ballistic Glazing Shot Pattern (500 × 500 mm)

Usage Notes

o The specimen is shown with a 500 mm edge.

o Shot centres marked with “X” are 120 mm apart.

o This is the standard triangular pattern required for EN 1063/EN 1522 tests.

EN 1063 / EN 1522 — Shot Pattern with Reference Coordinates

Usage Notes

o Centre of specimen is at (0,0).

o Distances are given in mm relative to centre.

o Particularly useful for test reports and documentation.

UL 752 and

NIJ 0108.01 — Typical Multi-Shot Grouping Layout

Example shot grouping area for UL 752 Levels 6/7 where five shots are permitted. Shot pattern is often specified with a 120 mm maximum horizontal spread; actual dimensioning should follow the applicable UL test method.

Usage Notes

o This diagram is illustrative; actual grouping tolerances should be taken from the official UL 752 text.

o You may adjust shot centre coordinates to match the specific UL

Are products ‘Bulletproof’ or ‘Bullet Resistant’

This is an age old anomaly and is best summarised by stating that nothing is actually ‘Bullet Proof’.

For example, a sample or product made in armoured steel can pass a ballistic test as outlined in the paragraphs above. Note that when testing, there is a specific arrangement or placement of shots onto the sample piece. Should the test be repeated several times in exactly the same place, then it could be found that eventually, one of the bullets will cause the material to fail in that exact spot and results in the bullet penetrating the test piece.

So to quantify this, the material is bullet resistant but not ‘bullet proof’ in the true meaning of the word. In real life situations, it is not common for several shots to be placed onto the same target point. Should this be of concern however, then the material would have to be upgraded and in doing so, then products would become far heavier and logistically more difficult to use in daily life.

Building upon this, it is important to always guard the level of ballistic protection that a product incorporates from public knowledge. Advertising that a product has ‘BR4 protection’ for example would immediately lead someone carrying out an unwarranted attack to simply use a BR5 or higher ballistic attack.