Ballistic Armour

Ballistic Armour

Available in steel or GRP sheet, which is cut to size, profiled by our in house design facility or customers can provide their own CAD drawings for direct input into CNC laser, plasma and water jet machines.

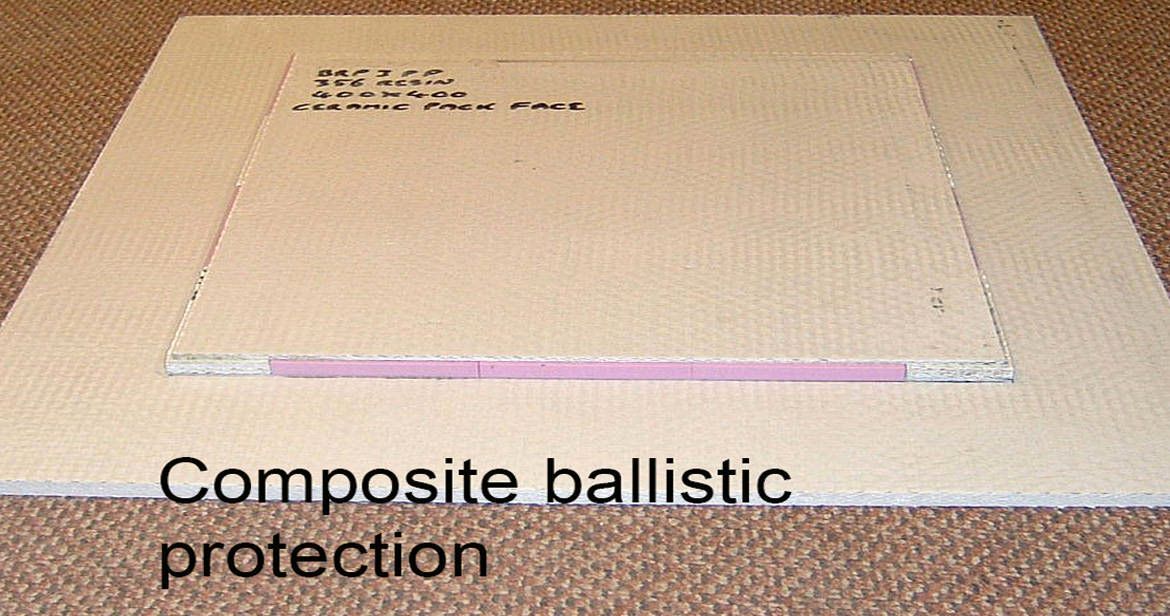

We can also provide steel fabrication and welding service and insulated pre-bonded steel and GRP ballistic sheets, particularly useful for

safe rooms or on site applications

Our ballistic armour sheets are designed for use in safe rooms, secure doors, walls, counters and control rooms, providing reliable protection against handgun and rifle threats. Panels can be supplied as single plates for your own fabrication or as pre-bonded composites for rapid installation, making them ideal for both new-build and retrofit security upgrades.

Typical sheet sizes and approximate areal weights for FB4–FB7 / NIJ IIIA–IV ballistic ratings are shown below to help you select the most suitable option for your project. If you’re unsure which level of protection you need, our technical team can advise on the best specification for your risk profile and installation method.

Blast & Ballistic Armour Specification

Steel – sheet sizes up to 6m x 2.5m

FB4, NIJ IIIA = approx 23kg/m

FB5/6, NIJ III = approx 48kg/m

FB7, NIJ IV = approx 120kg/m

GRP – sheet sizes up to 2.8m x 1.5m

FB4, NIJ IIIA = approx 26kg/m

FB5/6, NIJ III = approx 76kg/m

FB7, NIJ IV = approx 160kg/m

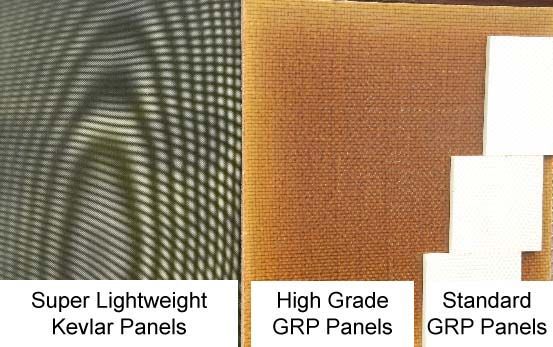

High grade GRP panels & Standard GRP panels

Insulated armoured panels, manufactured to size using steel or plastic/GRP materials. Rapid building of walls for on site applications. Reduces time and costs on site.

Kevlar is a synthetic fibre which is immensely strong when woven and bound with chemical agents. It is approximately 5 times stronger than steel on an equal weight basis

Bullet GRP consists of many layers of a special woven mat and is bonded under very high pressure with chemical agents to provide ballistic protection.

Building on these materials, our high grade GRP and Kevlar-reinforced panels provide a lightweight, practical alternative to traditional steel armour. Supplied as insulated armoured boards and manufactured to size, they make it easy to create secure linings, walls and partitions for safe rooms, control rooms, vehicle interiors and security counters.

Because the panels are factory-cut to suit your project, they allow rapid installation on site with minimal disruption. The multi-layer GRP and Kevlar construction spreads and absorbs impact energy, helping to stop handgun and rifle rounds while keeping overall panel weight low. This means standard studwork and existing walls can be upgraded to a tested ballistic specification without major structural changes.

We offer a choice of super lightweight Kevlar panels, high grade GRP panels and standard GRP boards, each with different performance, weight and cost benefits. The main advantages and disadvantages of Kevlar and GRP are outlined below.

Advantages/disadvantages

Kevlar – Extremely light, strong and versatile. The most expensive of all ballistic materials

GRP – Rigid sheet, heavier than Kevlar, good anti ricochet properties, can be cut on site with power tools but better if supplied cut to size from our factory. Cost effective and can be supplied in moulded shapes for special applications. Ideal for upgrading walls and studwork to provide

ballistic protection. Supplied unfinished and also available with decorative surfaces

Choosing between Kevlar and GRP will depend on the level of protection you need, the weight you can accommodate and the budget for your project. Kevlar panels offer exceptional strength at very low weight, while GRP ballistic boards provide a more cost-effective solution that is easy to work with on site and ideal for upgrading existing walls and structures.

To help you specify the right ballistic armour for your application, we’ve answered some of the most common questions about Kevlar panels, GRP ballistic sheets and their uses below.

Frequently Asked Questions

What is ballistic protection?

Ballistic protection is the use of specially engineered materials and constructions – such as steel armour plate, GRP ballistic panels and Kevlar composites – to stop bullets and fragments from firearms or explosive devices. Correctly specified ballistic protection prevents penetration and dangerous spall on the safe side of a wall, door or enclosure.

What are the main types of ballistic armour you supply?

We supply steel ballistic armour sheets, GRP ballistic panels and Kevlar-reinforced composites. Steel offers very high strength and durability, GRP provides a lighter, cost-effective board that’s easy to install, and Kevlar delivers maximum performance at the lowest possible weight. All options can be cut to size and profiled for your project

Which ballistic standards do your panels meet?

Our ballistic armour is designed and tested to recognised standards including EN 1522/1523 FB4–FB7 and equivalent NIJ IIIA–IV levels. These standards define the type of ammunition, velocity and number of shots a product must withstand, giving you a clear, tested level of protection.

Where is ballistic armour typically used?

Ballistic protection is widely used in safe rooms, control rooms, cash and ticket offices, secure counters, guard houses, vehicle interiors, doors, walls and partition linings. It is suitable for both new-build security projects and upgrading existing structures.

How do I choose between steel, GRP and Kevlar panels?

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.Can ballistic panels be fitted to existing walls?

Yes. GRP and Kevlar ballistic boards are ideal for lining studwork and existing masonry walls to upgrade them to a tested ballistic specification. Panels are supplied cut to size, ready to fix, which keeps disruption and installation time to a minimum.