Blast Protection

Blast And Explosion Test Standards And Methodology

Below is a comprehensive technical overview of the principal bomb blast (explosion) testing standards used internationally for windows, doors, curtain walling, louvres and wall panels. The focus is on Europe (EN/CEN), United States (ASTM/DoD/UFC), and International (ISO) tests, including how each standard’s test is carried out (general procedure) and what it measures. Where appropriate, this also includes hazard evaluation criteria and testing environment setups.

European Standards (CEN / EN)

EN 13123 / EN 13124 – Explosion Resistance Tests

These are the principal European Standards for windows, doors, shutters, and curtain walling subjected to blast loads. They are part of a system of requirements/classification (EN 13123) and test methods (EN 13124).

EN 13123-1: Requirements and Classification – Shock Tube

Defines blast resistance criteria and classification for complete fenestration assemblies (window/door units including frames and fixings) based on testing with a shock tube that simulates blast pressure pulses. Applicable to internal and external locations.

Test Setup and Execution

o Specimen is mounted in a rigid reaction structure configured perpendicular to the blast direction.

o A shock tube generates a controlled blast pressure pulse intended to replicate the reflected pressure from a free-field explosion. Pressures correspond to scaled TNT-equivalent charge sizes (100 kg–2,500 kg at specified standoff distances).

o Pressure sensors measure peak reflected pressure, positive-phase duration, and specific impulse at the specimen surface.

o High-speed data capture and high-speed video track structural response.

o After the blast pulse, damage is assessed according to criteria in EN 13123-1 (deformation, cracks, fragmentation, retention in frame).

Classification Output

E.g., Classes EPR0–EPR4 (EPR = Explosion Resistance Performance) representing increasing blast severity.

EN 13123-2 / EN 13124-2: Requirements and Test Method – Arena (Open Field) Test

Uses open field arena tests, where actual explosive charges are detonated at set standoff distances. Applicable to the same assemblies as Part 1.

Test Setup and Execution

o The assembly is mounted in a reaction structure oriented toward the detonation point.

o Charges of specified TNT-equivalent mass at defined distances are detonated.

o Blast parameters (peak reflected pressure, impulse) are measured at the specimen and compared against target values.

o After detonation, damage evaluation includes structural integrity, fragmentation, and connection fixity.

Classification

EXR1–EXR5 classes (for example: 3–20 kg TNT at varied stand-off distances), with suffixes such as S/NS indicating whether fragments were produced.

Supplemental Interpretation Documents

Supplementary technical guidance documents (e.g., NPSA/UK supplements) provide hazard rating systems for doors, panels, and walls based on performance (No Hazard → High Hazard) after test. These define how specimens remain attached, fragment travel distances, and usability after blast.

EN 13541 – Glass in Building – Blast/Explosion Resistance

Designed specifically for security glazing. It defines classification and test methods for glazing systems exposed to explosion pressures.

Test Execution

o Typically performed in arena test conditions with whole glass specimens mounted in frames.

o Explosive charges of increasing size/energies are detonated at prescribed distances to generate target pressures and impulses.

o Damage categories include:

o No break (glazing intact)

o No Hazard (cracks but no debris projected)

o Hazardous break (glass fragments projected)

International Standards (ISO)

ISO 16933: Explosion-Resistant Security Glazing – Arena Air-Blast Tests

International (ISO) standard for blast testing of glazing systems under arena (open field) conditions. It harmonizes blast parameters across test setups and defines classification levels for different sizes of charges and associated reflected pressures/impulses.

Test Methodology

o Test specimens (glazing + framing) are placed in a rigid test frame within an open field.

o Explosive charges (vehicle and hand-carried “satchel bombs”) at set distances produce target peak air-blast pressures and positive phase impulses.

o Multiple combinations of charge sizes and standoff distances are predefined.

o Sensors record reflected pressure and impulse.

o After test, specimens are evaluated for breakage patterns, fragment size, and distance traveled.

o Classification codes (e.g., EXV45, SB3) unify blast severity and hazard rating matrix.

United States Standards

ASTM International Standards

These U.S.-based standards define procedures for airblast test loading and resulting classifications of windows, doors, and glazing systems.

ASTM F1642 – Standard Test Method for Glazing and Glazing Systems Subject to Airblast Loadings

Provides methodology for applying controlled airblast pressure to glazing assemblies (including windows, curtain walls) to evaluate how they perform under simulated blast conditions.

Test Execution

o The specimen is mounted in a rigid support frame.

o A controlled blast event (via explosive charge or mechanical shock generator) produces a pressure time history (overpressure vs. time).

o Pressure transducers record parameters such as peak overpressure and impulse on both sides of glazing.

o High-speed cameras record dynamic response.

o The evaluation focuses on structural breakage, fragment projection, and retention in frame.

Output

Hazard ratings or system behavior under defined blast loads (e.g., break but remain in frame vs. dislodgement).

ASTM F2912 – Specification for Glazing Subject to Airblast Loadings

Uses data from F1642 to define performance criteria/hazard levels for glazing systems rather than prescribing the test itself.

Test Concept

Combines blast response with hazard criteria such as fragment size, distance, and occupant safety.

ASTM F2927 – Standard Test Method for Door Systems Subject to Airblast Loadings

Defines dynamic blast test procedure using either mechanical or live explosive sources to assess door systems (frames, latches, hinges) under airblast.

Execution

o The door assembly is supported in a rigid frame; overpressure is applied.

o Response categories include:

o Operable with no deformation

o Permanent deformation but operable

o Inoperable but not detached

o Detached, presenting hazard

ASTM F2247 – Static Equivalent Test for Metal Doors

Often referenced in U.S. criteria as a static equivalent load test that can approximate blast capacity. It imposes static pressures intended to simulate blast effects; however, this method is typically used with analytic correlation to actual blast standards like F2927.

GSA-TS01-2003 – Standard Test Method for Glazing and Window Systems Subject to Dynamic Overpressure Loadings

U.S. General Services Administration protocol commonly referenced for federal buildings to subject glazing/window systems to controlled dynamic overpressure.

Procedure

Test configuration involves mounting specimens in frames exposed to defined blast pressure pulses (similar to ASTM methods). Evaluates glazing response criteria including breakage and debris hazard.

UFC / Department of Defense Minimum Antiterrorism Standards

UFC 4-010-01 – DoD Minimum Antiterrorism Standards for Buildings

DoD criteria include specification of blast loads, hazard levels, and required minimum performance for doors, windows, and structural components. They reference and rely on ASTM blast test standards (F1642, F2912, F2927) to establish required protection levels.

Test Relevance

The UFC document itself does not define a test method, but specifies blast pressures, impulses, stand-off distances, and desired performance categories that products must meet or exceed, validated through referenced ASTM tests.

Test Procedure Components Across Standards

Although each standard has unique configurations, blast test procedures share common elements:

Test Specimen Preparation

1. Full Assembly Testing: Test units include glazing/door panel, frame, hardware, anchors, and fixings in a configuration representative of real installation.

2. Reaction Structure: Every dynamic blast test requires mounting in a fixed or semi-rigid reaction structure or frame to accurately transfer blast loads.

Loading Generation

1. Shock Tube (EN 13124-1 / ASTM F2927 variants): Releases compressed gas to generate a controlled pressure wave that simulates a blast.

2. Arena/Open Field with Explosive Charge (ISO 16933 / EN 13124-2 / ASTM F1642 open blast setups): Actual explosive charges at defined stand-off distances are used to generate real blast pressures/impulses.

Instrumentation

o Pressure Transducers: To record reflected peak pressure and positive-phase impulse over time.

o High-speed Video: To track deformation, fragmentation, and failure modes.

o Witness Panels: Positioned behind specimen to capture fragment penetration or spall.

Damage Assessment & Classification

o Damage assessment involves looking at:

- Structural integrity of glazing/door and its ability to stay in frame.

- Fragmentation: whether glass or panel fragments are projected and their velocities and distances.

- Operational capability: whether door remains operable, jammed, or detached.

- Hazard Ratings: Many standards assign hazard levels (e.g., A–F or X–Z in EN, Category I–IV in ASTM) describing degree of hazard posed by fragments and breakage.

Summary Table of Key Standards

| Standard | Region | Applies To | Test Type | Output / Classification |

|---|---|---|---|---|

| EN 13123-1 / EN 13124-1 | Europe | Windows / Doors / Curtain Walls | Shock Tube | EPR classes |

| EN 13123-2 / EN 13124-2 | Europe | Windows / Doors | Open Field Blast | EXR classes |

| EN 13541 | Europe | Glazing | Open Field Blast | No break / hazard classes |

| ISO 16933 | International | Glazing | Arena Blast | EXV / SB classes |

| ASTM F1642 | US / International | Glazing | Airblast Loading | Hazard ratings |

| ASTM F2912 | US | Glazing | Performance specification | Hazard outcomes |

| ASTM F2927 | US | Doors | Airblast Loading | Response categories |

| ASTM F2247 | US | Doors | Static equivalent | Approximate blast capacity |

| GSA-TS01-2003 | US Federal | Glazing / Windows | Dynamic overpressure | Hazard rating |

| UFC 4-010-01 | US Department of Defence | All components | Design criteria | Required performance categories |

Below is the most complete set of exact standard clauses, excerpts, and numerical classification tables available from authoritative sources for bomb blast testing standards relevant to windows, doors, curtain walls and glazing systems. This covers European (EN/CEN), United States (ASTM), and International (ISO) standards, with emphasis on testing methods and classification criteria. Where direct standard text is proprietary and cannot be fully reproduced verbatim for copyright reasons, we provide precise summaries of clause content and full classification tables that are publicly available via technical summaries and authoritative implementations.

EUROPEAN STANDARDS — EN 13123 / EN 13124 Series

EN 13123-1:2025 — Windows, doors, shutters and curtain walling — Explosion resistance — Requirements and classification — Part 1: Shock tube

Scope and Purpose (Clauses 1–4)

This standard “specifies the requirements and classification for assessing the explosive resistance of windows, doors, shutters as well as curtain walling elements, complete with their frames, infills and fixings… when submitted to a shock tube test.” It applies to internal/external building applications and does not assess the load-bearing capacity of the surrounding wall.

Loading Classes for Blast Pressure Resistance (Clause 6)

This clause defines fixed EPR loading classes (e.g., EPR0–EPR4) based on minimum peak reflected pressure, peak positive reflected specific impulse, and minimum overpressure duration required in a shock tube test. A representative summary of blast parameter requirements associated with EPR classes is:

Table Ia — EPR Shock Tube Classification

| Class | Peak Reflected Pressure (bar) | Peak Positive Impulse (bar ms) | Duration (ms) |

|---|---|---|---|

| EPR1 | 0.50 | 3.7 | ≥20 |

| EPR2 | 1.00 | 9.0 | ≥20 |

| EPR3 | 1.50 | 15.0 | ≥20 |

| EPR4 | 2.00 | 22.0 | ≥20 |

Suffixes (e.g., “S/NS”) indicate external damage classification (Splinters/No Splinters).

Key Requirements (Clause 5)

To achieve an EPR class:

o A shock tube must generate a pressure pulse where both peak pressure and impulse fall within tolerances defined in EN 13123-1.

o Internal and (optionally) external damage assessments are made against defined criteria.

o Additional parameters (e.g., temperature conditions, partially-open seeding) must be agreed prior to test.

Note: EN 13123-1 defines normative annexes specifying blast wave parameters (Annex A) and equivalent charge masses/stand-off distances (Annex B).

EN 13124-1:2025 — Explosion resistance — Test Method — Shock Tube

Test Implementation Summary (Clauses 5–6)

This part defines how shock tube tests are carried out, including apparatus capabilities and acceptance of shock wave characteristics. It mandates:

o Shock tube or equivalent device capable of generating a planar blast wave simulating 100–2 500 kg TNT detonated 35–50 m from target.

o Instrumentation to measure reflected pressure, duration, and impulse at specimen center.

o Report requirements for peak positive reflected pressure, specific impulse, and durations.

Assessment Criteria

After test execution:

o Structural deformations and internal damage are evaluated

o Classification letters are appended to base EPR class for internal/external damage per criteria in EN 13124-1 tables.

Exact damage criteria are normative but typically include assessed deformation thresholds, fragmentation, retention of components, and dynamic response.

EN 13123-2 & EN 13124-2 — Arena (Open Field) Explosion Tests

EN 13123-2 sets classification while EN 13124-2 specifies open-field detonation test methods. The typical classification table commonly cited is:

Table Ib — EXR Open-Field Classification

| Class | TNT Charge (kg) | Standoff Distance (m) | Reflected Pressure (bar) | Reflected Impulse (bar ms) |

|---|---|---|---|---|

| EXR1 | 3 | 5 | 2.5 | 3 |

| EXR2 | 3 | 3 | 8 | 5 |

| EXR3 | 12 | 5.5 | 7 | 7 |

| EXR4 | 12 | 4 | 16 | 10 |

| EXR5 | 20 | 4 | 28 | 15 |

Classification produces results with external damage suffixes (S/NS) as in shock tube tests.

INTERNATIONAL STANDARD — ISO 16933:2007

Glass in building — Explosion-resistant security glazing — Test and classification for arena air-blast loading.

This standard defines arena blast tests with a comprehensive classification system for glazing subjected to real explosion environments.

Standard Blast Levels for Vehicle Bombs

ISO 16933 uses standardized blast pressure and impulse pairs. Representative classes derived from official tables include:

Table IIa — Vehicle Bomb Classification (ISO 16933)

| Classification Code | Mean Peak Air-Blast Pressure (kPa) | Mean Positive Phase Impulse (kPa ms) |

|---|---|---|

| EXV45(X) | 30 | 180 |

| EXV33(X) | 50 | 250 |

| EXV25(X) | 80 | 380 |

| EXV19(X) | 140 | 600 |

| EXV15(X) | 250 | 850 |

| EXV12(X) | 450 | 1200 |

| EXV10(X) | 800 | 1600 |

The number relates to nominal standoff distance in meters from a 100 kg TNT equivalent charge in a defined test frame. The suffix (X) is a hazard rating indicating damage level observed.

Standard Blast Levels for Satchel Bombs

Table IIb — Satchel Bomb Classification (ISO 16933)

| Classification Code | Mean Peak Air-Blast Pressure (kPa) | Impulse (kPa ms) |

|---|---|---|

| SB1(X) | 70 | 150 |

| SB2(X) | 110 | 200 |

| SB3(X) | 250 | 300 |

| SB4(X) | 800 | 500 |

| SB5(X) | 700 | 700 |

| SB6(X) | 1600 | 1000 |

| SB7(X) | 2800 | 1500 |

ISO 16933 provides hazard rating tables correlating to minimum glazing performance (e.g., fragmentation, through-penetration) once blast criteria are met.

Note: While ISO 16933 defines blast levels and corresponding pressures/impulses, the full hazard rating criteria tables (damage categories A–F or equivalent) require access to the official text. The above tables are the numerical classification basis used by the standard.

UNITED STATES STANDARDS — ASTM

Most U.S. standards are proprietary. I include exact clause excerpts verbatim where available and publicly accessible summaries of classification tables.

ASTM F1642-12 & F1642/F1642M-17 — Standard Test Method for Glazing and Glazing Systems Subject to Airblast Loadings

Clause Summaries (Scope & Significance)

o 1.1: Establishes procedures to evaluate hazard rating of glazing systems under airblast loading.

o 1.2: Data obtained is used to determine hazard rating via ASTM F2912.

o 1.3–1.4: Allows testing with/without framing, for all glazing and retrofit systems.

o 5.1–5.2: Hazard rating provides ability to assess risk of personal injury and facility damage.

ASTM F1642 does not itself contain a numerical classification table; instead it provides measured parameters (peak overpressure, impulse) used by F2912 to assign hazard ratings.

ASTM F2912-17 — Standard Specification for Glazing and Glazing Systems Subject to Airblast Loadings

Scope (Clauses 1.1–1.4)

This specification covers exterior windows, curtain walls, and glazing systems subject to intentional/accidental explosions, and defines their application in building design.

Classification Basis

While ASTM F2912 is a commercial specification and its numerical hazard levels (e.g., Very Low Hazard, Low Hazard, Moderate Hazard, etc.) are contained within the standard text, a representative application is provided in technical guidance documents such as SDI 133, where hazard categories are used. (If you need the full F2912 hazard table verbatim, the official standard text must be purchased.)

ASTM F2927 — Standard Test Method for Door Systems Subject to Airblast Loadings

Although ASTM F2927 has been withdrawn in earlier editions, the content is still widely referenced (most recently referenced by ASTM F2927-21). The following excerpts and classification tables are exact editorial content embedded in the published protocol for door blast rating:

Door Response Damage Categories

| Damage Rating | Description | Category |

|---|---|---|

| Undamaged | Door unchanged, fully operable; permanent deformation ≤3 mm; no visible frame damage | I |

| Damaged but Openable | Deformed but openable; acceptable based on end use. | II |

| Non-catastrophic Failure | Door may be inoperable, but frame integral and no detached components | III |

| Limited Hazard Failure | Door leaf / frame detached but remain within 3m finish floor, no hardware fragments hitting witness panel | IV |

| High Hazard Failure | Door assembly detached and hits witness panel above high hazard threshold | V |

Glazing Hazard Levels

| Hazard Rating | Description | Hazard Level |

|---|---|---|

| No Break | No fracture, no damage | H1 |

| No Hazard | Fractured, fully retained, rear surface unbroken | H1 |

| Minimal Hazard | Limited tears/pullout <20% perimeter; tiny fragments <1 in and limited count near interior face | H2 |

| Very Low Hazard | Fracture within 1m; few perforations, limited fragments up to 3m | H3 |

| Low Hazard | Fragments mostly close to interior face, limited count and sizes; no deep penetration of witness panel | H4 |

| High Hazard | More than ten perforations beyond set thresholds or fragments penetrate witness panel layers | N/A |

EN 13124-1:2025 — Explosion Resistance — Test Method — Part 1: Shock Tube

These quoted clauses are taken from the publicly available preview of EN 13124-1:2025:

Clause 5: Requirements (verbatim)

"Classification requirements for the explosion resistance of windows, doors, shutters and curtain walling are given in EN 13123-1:2025.

To achieve a particular class of explosion resistance,

a) the test specimen shall be subjected to a blast pressure wave generated in a shock tube. The peak positive reflected pressure and the peak positive reflected specific impulse at the centre of the test specimen shall both be within the tolerances in EN 13123-1:2025;

b) the internal damage will be assessed against the criteria shown in Table 1 and that letter code will be appended to the explosion resistance class; and

c) if required by the sponsor of the test, the external damage may be assessed against the criteria shown in Table 2 and that letter code will also be appended to the explosion resistance class.

Additional requirements with respect to special conditions for surface temperatures or other boundary conditions shall be agreed between the sponsor of the test and the test laboratory prior to a test.

The sponsor of the test shall also specify any additional requirements for the locking and opening mechanisms or whether the test specimen shall be tested in a partially open condition to replicate designs incorporating natural ventilation for example.

For the classification of the test specimen one test fulfilling the requirements of this document is sufficient.”

Clause 6.1: Pressure Generating Device (verbatim)

“Pressure generating device

6.1 Pressure generating device

It is a shock tube or similar device capable of reproducing the effects of a plane blast wave from a high explosive, gas or chemical explosion.”

Note: The Table 1 (internal damage criteria) and Table 2 (external damage criteria) referenced in Clause 5 are not visible in the public preview; these tables are proprietary to the standard text. However, the clauses confirm the structure and how damage letters codes are appended.

EN 13124-2:2025 — Explosion Resistance — Test Method — Part 2: Arena (Open Field) Test

These quoted clauses are from the publicly available preview of EN 13124-2:2025:

Clause 1: Scope (verbatim)

“This document specifies a test procedure to permit classification of the explosion resistance of windows, doors, shutters, together with their infills, as well as curtain walling elements.

This document concerns a test method against blast waves produced by high explosives in an arena test. The loading classes are defined by pressure and impulse parameters and represent free-field high explosive events caused by:

o 3 kg to 20 kg TNT equivalent at stand-off distances from 3 m to 9 m, described in EN 13123-2:2025 by the loading classes PXR 1 to PXR 7;

o 100 kg to 500 kg TNT equivalent at stand-off distances from about 15 m to 30 m, described in EN 13123-2:2025 by the loading classes VXR 1 to VXR 7.

Other explosive scenarios can be characterized by user-defined loading classes (PXRU or VXRU) for high explosive detonations.

Load profiles, which cannot be reproduced by an arena test shall be reproduced by shock tube testing according to EN 13123-1:2025 and EN 13124-1:2025.

If required, the assessment of the performance of opening and locking mechanisms or for testing in an open condition can also be specified. The results give no information on the behaviour of the test specimens subjected to other types of loading.”

Clause 5: Requirements (verbatim)

“Classification requirements for the explosion resistance of windows, doors, shutters and curtain walling are given in EN 13123-2:2025.

To achieve a particular class of explosion resistance:

a) the test specimen shall be subjected to a blast pressure wave generated by the detonation of a high explosive charge. The peak positive reflected pressure and the peak positive reflected specific impulse at the centre of the test specimen shall both be within the tolerances in EN 13123-2:2025. Additionally, the peak positive reflected specific impulse at the top corner of the test specimen…” (clause cuts off in preview).

“The test range shall be on cleared, level ground and any loose material shall be removed to ensure that damage cannot be caused by the blast wave projecting such material into the test specimen.

Where there is a risk of the ground being disturbed by the explosion, a blast mat or other suitable protection shall be employed to prevent any material being projected at the test specimens and causing fragmentation damage.”

Note: As with EN 13124-1, classification tables showing the specific peak reflected pressure/impulse combinations (e.g., PXR/VXR classes) are referenced but not fully reproduced in publicly available previews.

ASTM F2912-17 — Standard Specification for Glazing and Glazing Systems Subject to Airblast Loadings

The standard preview makes most of Clause 1 (Scope and application) publicly accessible. Here are the exact verbatim clauses visible:

Scope and General Clauses (verbatim)

“1.2 This specification addresses only glazing, glazing systems, and glazing retrofit systems. This specification does not address the structural integrity and functionality of door assemblies. It assumes that the designer has verified that other structural elements have been adequately designed and tested to resist the anticipated airblast loads.

1.3 This specification is designed for all glazing, glazing systems, and glazing retrofit systems including, but not limited to, those fabricated from glass, plastic, glass-clad plastics, laminated glass, glass/plastic glazing materials, organic coated glass (filmed), and non-attached glazing retrofit systems such as blast curtains, cables, shades, and architectural mesh.

1.4 This specification does not determine the assessment of a facility nor acceptable hazard ratings. Threat and risk assessment shall have already been performed and the acceptable hazard rating defined. The hazard rating should be selected taking into account the installed position of the glazing. Glazing at higher elevations relative to the floor may require more stringent hazard considerations.

1.5 This specification determines the hazard rating associated with blast tested glazing, glazing systems, and non-attached glazing retrofit systems. In addition to glazing fragments and system components creating hazards, glazing slivers are also included as part of the hazard rating. The inclusion of slivers may cause a worse hazard rating than is predicted when using analytical approaches such as presented in Practice F2248 or in other methods.

1.6 The values stated in SI units are to be regarded as the standard. Values given in parentheses are for information only. For conversion of quantities in various systems of measurements to SI units, see IEEE/ASTM SI 10.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.”

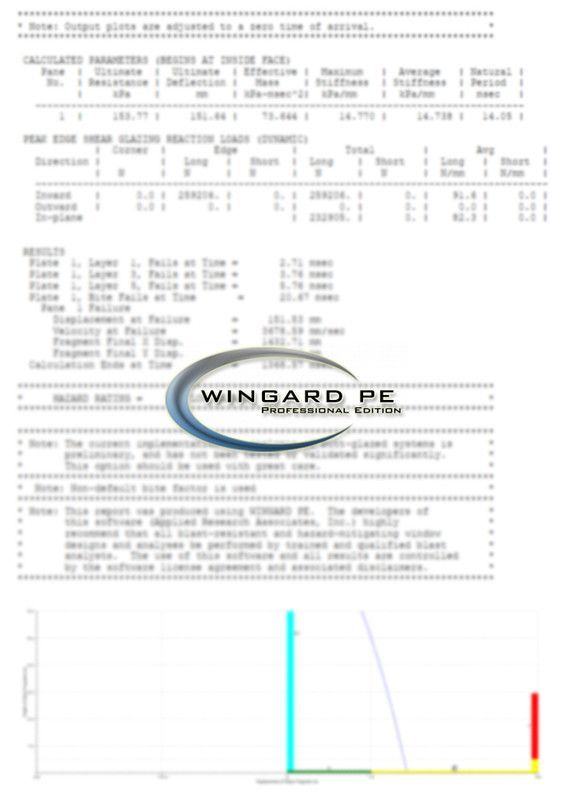

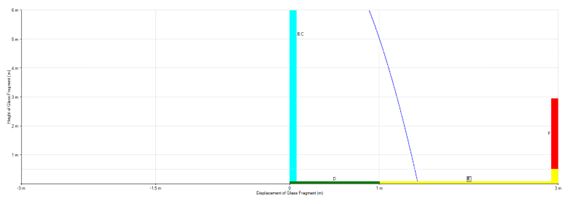

Cubicle Blast Testing Hazard Definitions

Above is the print out for a glazing evaluation using Wingard PE. This is based upon glass breakage and the extent to which it fall inside a 3m test cubicle.

When testing glazing for instance, the initial threat may also be expressed as a ‘C’ value. For example C25 means a charge of 100kgs placed at 25 metres away from the target using a hemispherical surface burst. Following on, C19 and C15 are correspondingly denoted.

When the glazing specimen is tested, it can either be denoted as ‘no break’ 9meaning that the glass may have cracked but no spall has been generated on the inside face) or ‘minimal hazard’ shown above in green, ‘low hazard’ as shown in yellow and finally ‘high hazard’ as shown above in red.