Ballistic And Bullet Resistant Windows, Glazed Doors And Screens

DOWNLOAD TECHNICAL DATA SHEET

Ballistic And Bullet Resistant Windows And Screens

- Ballistic Windows, Glazed Doors and Screens offer bullet resistance in high-risk environments which face a range of threats.

- Bullet resistance up to EN1063 BR7, BS EN 1522/23 FB7, UL752 Level 8 and NIJ 0108.01 Level IV.

- Manufactured in aluminium and steel profiles.

- Available for primary and secondary applications.

- Units can be single or double glazed.

Product Description

The product is used in a range of applications, ranging from commercial buildings, resdiential housing and military environments.

We are able to offer protection against a wide range of ammunition and to numerous standards all over the world.

Advantages

Our ballistic windows, glazed doors and screens have been tested against the appropriate standards. We issue full and complete test reports to customers to satisfy Health and Safety requirements.

Features

- Test reports available for each product.

- Frames are PPC finish as standard to a chosen RAL colour with special finishes available upon request.

- Supply only or supply and install service available.

| PROFILE |

|---|

| Aluminium profiles available |

| Steel profiles available |

| FINISHES |

|---|

| Factory Polyester Powder Coat (PPC) finish |

| Mill Finish |

| AVAILABLE SIZES |

|---|

| Minimum 300mm wide x 500mm height |

| Maximum 2200mm wide x 4000mm height |

| Indefinite sizes with combination of multiple units |

| WEIGHTS |

|---|

| Varies with ballistic / bullet resistance required |

| STANDARDS & CALCULATIONS |

|---|

| Test reports available upon request |

| SHIPPING |

|---|

| Supplied in International Shipping Crates for dispatch or full install service offered |

Typical Areas of Application

· Chemical Production

· Petroleum Industry

· Paint, Varnish Manufacturers

· Energy/ Mining Industry

· Co-Generation Plants

· Recycling Centres

· Sewage Treatment (by-product recycling)

· Automotive (air bag, mfg. Plant lines)

· Grinding/Pulverizing processes (airborne dusts)

· Ink Manufacturers

· Energy Storage Systems (ESS)

· Industrial Processing Equipment

· Paper Process (solvent use/storage)

· Laboratory Test Facilities

· Hospitals (gas and/or flammable storage areas)

· Brewery Facilities (grain storage/processing)

· Fossil Fuel Plants (coal dusts)

· Food Processing (airborne dust)

· University Labs (chemical lab store rooms)

· Grain Milling Facilities (airborne dusts)

· Nuclear Power Stations

· Printing Companies (solvent use/storage)

· Gas/Vapour Handling Equipment

· Dust Collection Systems

Levels of Ballistic Protection And Bullet Resistance

We offer ballistic / bullet resistant windows up to EN1063 BR7, EN1522/23 FB7, UL752 Level 8 and NIJ 0108.01 Level IV.

| Standard | Scope | Threat Basis | Classification Units | Key Outcome |

|---|---|---|---|---|

| EN 1063 | Ballistic glazing | Bullets, shotguns | BR1 - BR7, SG1 / SG2 | No penetration plus spall status |

| EN 1522/1523 | Complete windows / doors | Bullets, shotguns | FB1 - FB7 (+FSG) | No penetration (structural) |

| UL752 | Bullet-resisting equipment and assemblies | Handguns and riflles | Level 1 - 8 + | No penetration plus no dangerous spall |

| ASTM F1233 | Security glazing and forced entry | Bullets and tools | 11 classes | Combined ballistic and tool resistance |

| NIJ 0108.01 | Ballistic resistant materials | Defined calibres | NIJ levels | No perforation |

| UL Level | Ammunition | Calibre | Bullet Type / Weight | Velocity (m/s) | Velocity (ft/s) | Shots |

|---|---|---|---|---|---|---|

| Level I | .22 Long Rifle HV | .22 LR | Lead Round Nose, 40 gr (2.6g) | 320 +/- 12 | 1,050 +/- 40 | 5 |

| Level I | .38 Special | .38 Spl | Lead Round Nose, 158 gr (10.2g) | 259 +/- 15 | 850 +/- 50 | 5 |

| Level IIA | 9mm Parabellum | 9 x 19mm | FMJ, 124 gr (8.0g) | 332 +/- 12 | 1,090 +/- 40 | 5 |

| Level IIA | .357 Magnum | .357 Mag | Jacketed Soft Point, 158 gr (10.2g) | 381 +/- 15 | 1,250 +/- 50 | 5 |

| Level II | 9mm Parabellum | 9 x 19mm | FMJ, 124 gr (8.0g) | 358 +/- 12 | 1,175 +/-40 | 5 |

| Level II | .357 Magnum | .357 Mag | Jacketed Soft Point, 158 gr (10.2g) | 425 +/- 15 | 1,395 +/- 50 | 5 |

| Level IIIA | 9mm Parabellum | 9 x 19mm | FMJ, 124 gr (8.0g) | 426 +/- 15 | 1,400 +/- 50 | 5 |

| Level IIIA | .44 Magnum | .44 Mag | Lead SWC GC, 240 gr (15.55g) | 426 +/- 15 | 1,400 +/- 50 | 5 |

| Level III | 7.62mm NATO | 7.62 x 51mm | FMJ, 150 gr (9.7g) | 838 +/- 15 | 2,750 +/- 50 | 5 |

| Level IV | .30-06 Sprinfield AP | .30-06 | Armor / Armour-Piercing, 166gr (10.8g) | 868 +/- 15 | 2,850 +/- 50 | 1 |

| Class | Weapon Type | Calibre | Bullet Type | Mass (g) | Velocity (m/s) | Energy (J) | Range (m) | Shots |

|---|---|---|---|---|---|---|---|---|

| BR1 | .22 LR | .22 LR | Lead RN | 2.6 | 360 +/- 10 | ~168 | 10 | 3 |

| BR2 | Handgun | 9 x 19mm Luger | Full Jacket / RN / Soft Core | 8.0 | 400 +/- 10 | ~640 | 5 | 3 |

| BR3 | Handgun | .357 Magnum | Full Jacket / Conical / Soft Core | 10.2 | 430 +/- 10 | ~940 | 5 | 3 |

| BR4 | Handgun | .44 Rem Magnum | Full Jacket / Flat Nose / Soft Core | 15.6 | 440 +/- 10 | ~1,510 | 5 | 3 |

| BR5 | Rifle | 5.56 x 45mm NATO | Full Jacket / Pointed Soft Core / SS109 | 4.0 | 950 +/- 10 | ~1,805 | 10 | 3 |

| BR6 | Rifle | 7.62 x 51mm NATO | Full Jacket / Pointed Soft Core | 9.5 | 830 +/- 10 | ~3,272 | 10 | 3 |

| BR7 | Rifle (AP) | 7.62 x 51mm NATO | Full Jacket / Pointed Hard Core | 9.8 | 820 +/- 10 | ~3,295 | 10 | 3 |

| SG1 | Shotgun | 12 Guage (70mm) | Solid Lead Slug | 31 | 420 +/- 20 | ~2,734 | 10 | 1 |

| SG1 | Shotgun | 12 Gua | Solid Lead Slug | 31 | 420 +/- 20 | ~2,734 | 10 | 3 |

Ballistic Windows / Screens & Entrances

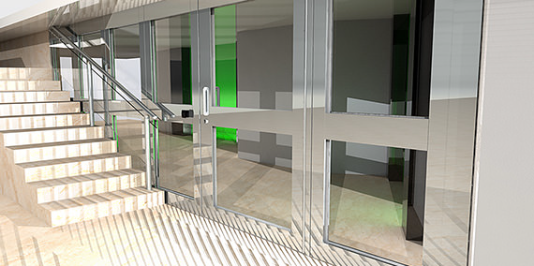

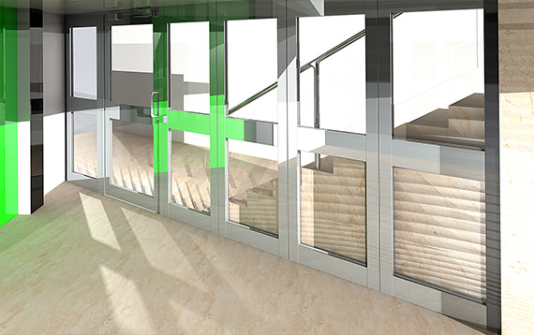

There has always been a desire to create buildings and entrances with as much ‘open space’ as possible. However pleasant and modern that environment may feel, it does become problematic when we then try to incorporate security and in particular ballistic protection.

The transition between ‘open space’ and solid structures is transparent armour, known simply as ‘ballistic’ or ‘bullet’ glass. This can occupy as much as 90% or more of a ballistic screen or entrance. With this much glass in any screen or entrance it still provides the feeling of ‘open space’ yet provides the security and assurance that we need.

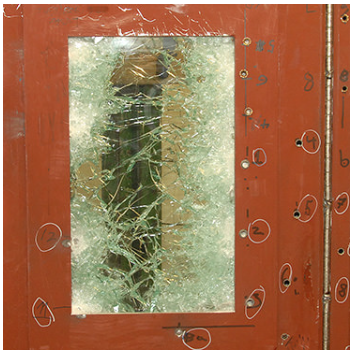

We supply ballistic and bullet resistant entrances as fully tested products. Not simply the glass itself but all elements of the framework and also the entrance door. Incorporating access control, card readers, intrusion detection, it all combines to provide a secure, turnkey ballistic and bullet solution.

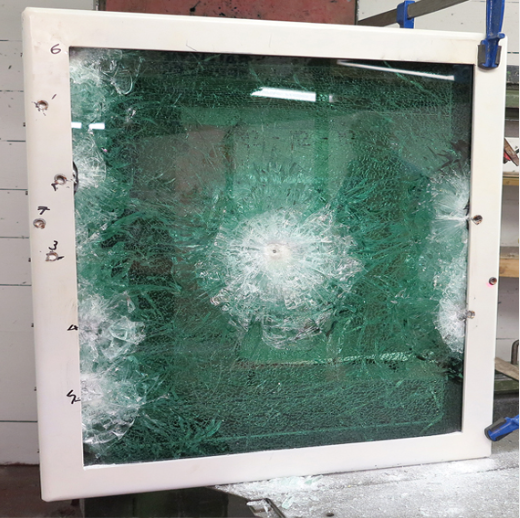

Illustrated below are examples of ballistic and bullet tested screens and entrances, showing how both the glass and also the framework itself is tested in independent test centres.

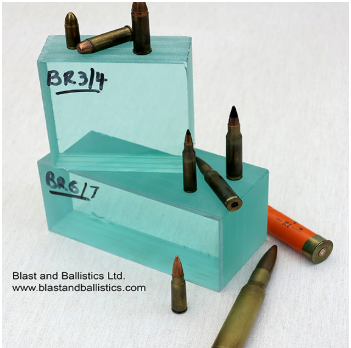

Ballistic glass, sometimes also referred to as ‘bullet glass’, is constructed of several layers of glass, PVB and sometimes with the addition of specialist polycarbonates. These layers gradually erode the penetration of the bullet when it strikes the glass. Shown below are examples of both BR4 and also BR6/7 glazing. BR4 and BR6/7 glazing references are derived from BS EN1522/23 European testing but we also supply ballistic and bullet solutions for NIJ and also UL levels of ballistic protection. UL levels up to UL 752 level 8 and also NIJ IV.

The incorporation of stainless steel finishes and low ion glass also provide that ‘open space’ feeling but still provide the comfort of knowing that everything has been tested to provide the level of protection that is expected.

Aluminium Ballistic Windows

In certain instances, some projects require windows fabricated in aluminium rather than steel. This may be either to complement the overall building appearance or to provide a ‘thermal break’ for energy efficient projects.

The inclusion of a thermal break within the framing system helps to reduce the transmission of either warm or cool temperatures passing from one side of the frame to the other. Our aluminium

bullet windows accommodate a range of protection levels and can also be incorporated into large screens and joined together to create even larger units as used in facades, interlocks and rooms. They are suitable for both internal and external applications.

Slow Motion Video of Window System Under Ballistic Test

Click on the link to see high speed footage of the window framing under test. The speed has been reduced to approximately 1 frame per second and the bullet is seen to strike the window frame system and fragment.

The bullet was travelling at 836 metres per second and even using high speed cameras it still appears to travel quickly.

How thick is the glass itself ?

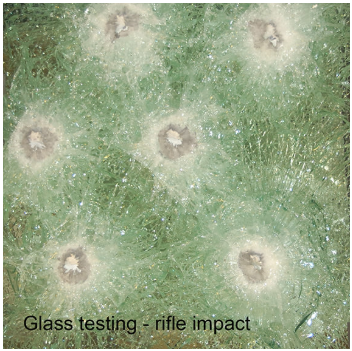

That will vary upon the protection level that is required. Generally ranging from around 24mm through to as much as 82mm in thickness. Below are images of glass that has been tested under laboratory conditions. Multiple shots within a confined area.

Is there one specific threat that can be used as a general guide when ordering protection ? That can be difficult to answer. There are established practices in different areas, for want of a better description but this then becomes an area where risk versus cost may also become an issue and although ‘planning for the worst’ may be desirable, it may not actually become achievable.

Mitigating the greater element of risk is always better than preparing to do nothing. Handguns are easily concealed and in commercial premises where there is usually a threat in connection with money such as Banks or Shopping premises, then we would often consider ballistic levels up to BS EN1522/23 BR4 or NIJ IIIA (.357, .44 calibre) to be sufficient. However, across the Middle East in general, then the major threat has to be the Kalashnikov AK47 assault weapon. This is almost universal in many areas of this Region. However, within this theatre of conflict there are also other assault rifles which extend beyond this using ammunition such as NATO 5.56 and also 7.62.

Extending that even further we also find .50 calibre weapons in use and again that is another level of threat that we must sometimes consider.

From time to time it may be suggested that the addition of window film would provide ballistic protection to existing glazing. That is extremely unlikely and optimistic. At best it may help to alleviate spall internally but again that would still require the glass to have some initial ballistic resistance. It is better to have certificated glass from the onset and then the way forward is perfectly clear so to speak.

Heat tempered glass is also a consideration when carrying out installations in Middle Eastern regions. Quite often the temperature difference between the outside and inside of the glass can vary dramatically. Direct sunlight externally and air conditioning internally. This can sometimes create a temperature differential of between 20 and 30 degrees.

It is sometimes suggested that bullet or ballistic glass is also a good choice for security and physical attack. This is a misnomer because it may be good at stopping the impact from a bullet but it is not good at resisting sustained physical attack. It is brittle and can be penetrated with hand tools.

A good compromise where bullet and attack resistance is needed is to use a glass-polycarbonate hybrid glazing unit. This will still arrest the bullet and the polycarbonate will resist the physical impacts associated with hand tools and also repetitive and localised areas of attack.

Specification

| Window Type | Certified | Glazed Test | Windowleaf Test | Window frame Test | Lock Test | Hinges Test | Gap Tests |

|---|---|---|---|---|---|---|---|

| Veneered / Painted Timber Windows | FB4 & BR4 FB5/6/7 AK47 + NIJ III Inwards & Outwards Opening Single + Double | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Steel Windows | FB4 & BR4 FB5/6/7 AK47 + NIJ III Inwards & Outwards Opening Single + Double | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Fully Glazed Panels | FB4 & BR4 FB5/6/7 AK47 + NIJ III Inwards & Outwards Opening Single + Double | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Glazed Panel Door | FB4 & BR4 FB5/6/7 AK47 + NIJ III Inwards & Outwards Opening Single + Double | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

We also have certification for products falling within BS 5051, NIJ & U L equivalents. Continuous product testing enables us to accommodate variations across any of our products to suit customers specific requirements.

| Tested | ||

|---|---|---|

| Lower Vents | FB4 & BR4 FB5/6 & BR5/6 AK47 | ✔ |

| Vision Windows | BR4, BR5/6 & BR7 AK47 + NIJ III, NIJ IIIA | ✔ |

Louvered vents are designed for installation into doors, walls, partitions, and screens. Internally and externally. Saferooms, plant rooms, chiller rooms and so forth. They can be supplied with a catch tray to prevent ingress of flammable liquids in the event of a terrorist attack. The combustible fuel drains back out to the outside of the building.

Door viewers are designed to accomodate door/panel thickness from 30mm up to over 100mm in depth.

Vision panels are designed and tested for installation into wooden or steel doorsets. They are also used in the design of side screens and fanlights above doorsets.

Windows available with different sections for all building applications.

7.62 ‘Armour Piercing’ Window Protection System

Our Universal Window system has now been independently tested and certified to protect buildings up to 7.62 Armour Piercing ammunition.

Available in made to measure sizes and a range of colors, this product has been tested to meet:

- BS EN 1522/23 BR7 – 7.62 x 51mm FN Armour Piercing Ammunition - (Test report No. 10418a)

- NIJ 0108.01 level IV – 30-06 FN M2 AP 166gr Armour Piercing Ammunition (Test report No. 10418a)

- UL 752 Level 9 – 30-06 FN M2 AP 166gr Armour Piercing Ammunition (Test report No. 10418a)

Features

- Cost effective

- Manufactured to any size

- Available in a wide range of colors

- Ease of installation

- Independently tested

- Supply only or full survey and installation

- Available with Spall or No Spall glass

- Also available with low iron glass

Our ballistic window service includes

Handling the following applications

- Glass Facades

- Windows

- Doors

- Screens

Using the best quality materials

- Made in Steel & Aluminum

- Blast Rated

- Security Rated

- Bullet Rated

Frequently Asked Questions

What is a ballistic window?

A ballistic window is a complete bullet-resistant window system – not just the glass. Blast & Ballistics windows include tested glass, frame and opening sections to stop handgun and rifle fire while maintaining visibility and an open, modern feel. Systems are supplied as fully tested screens, entrances and windows, rather than loose panes of glass.

How are Blast & Ballistics ballistic windows different from standard ‘bulletproof glass’?

Standard “bulletproof glass” is usually just a glass package. Blast & Ballistics supplies fully engineered ballistic windows, doors and screens, where the glass, framing and door leaves are all tested together in independent test centres. The result is a complete entrance or façade with certified protection levels, integrated with access control, card readers and intrusion detection if required.

What ballistic levels can your windows achieve?

Our ballistic glazing is available in configurations to meet BR4 and BR6/7 levels to BS EN 1522/23, and we also supply solutions tested to UL 752 up to Level 8 and NIJ Level IV. For higher threats, our Universal Window System has been independently tested to 7.62 armour-piercing (BR7), NIJ 0108.01 Level IV and UL 752 Level 9.

How thick is ballistic window glass and what is it made from?

Glass thickness depends on the required protection level, typically ranging from about 24 mm up to around 82 mm. Our ballistic glass is built from multiple layers of glass, PVB interlayers and sometimes specialist polycarbonates, which progressively erode the bullet’s energy and prevent perforation. Options include Spall and No Spall glass and low-iron glass for maximum clarity

Do ballistic windows also protect against physical attack and forced entry?

Ballistic glass is designed to stop bullets but, on its own, it is not ideal against sustained physical attack with tools, because glass is inherently brittle. For projects needing both bullet resistance and strong manual attack performance, we recommend glass–polycarbonate hybrid glazing units – the glass stops the bullet and the polycarbonate layer resists repeated blows and tool attack.