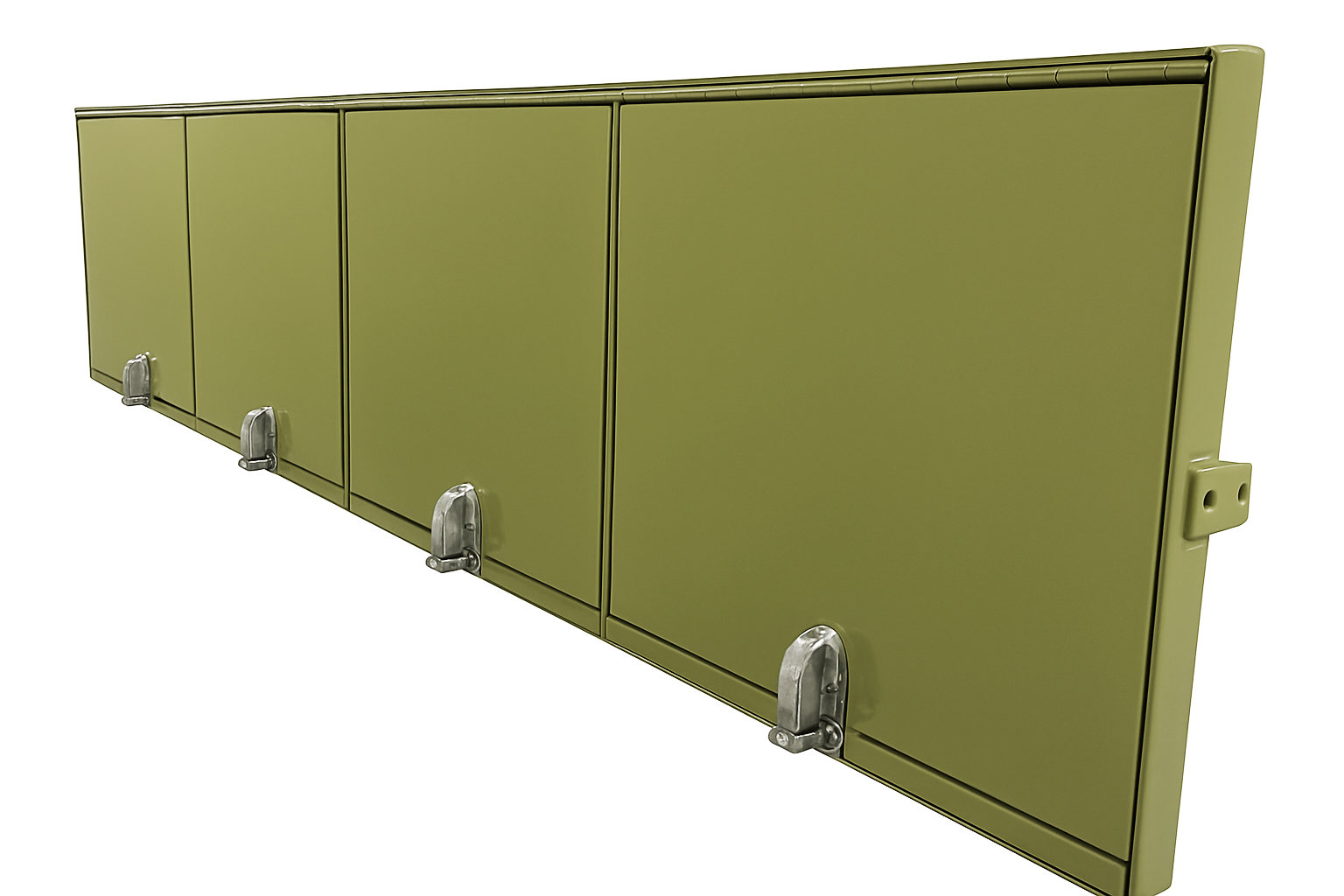

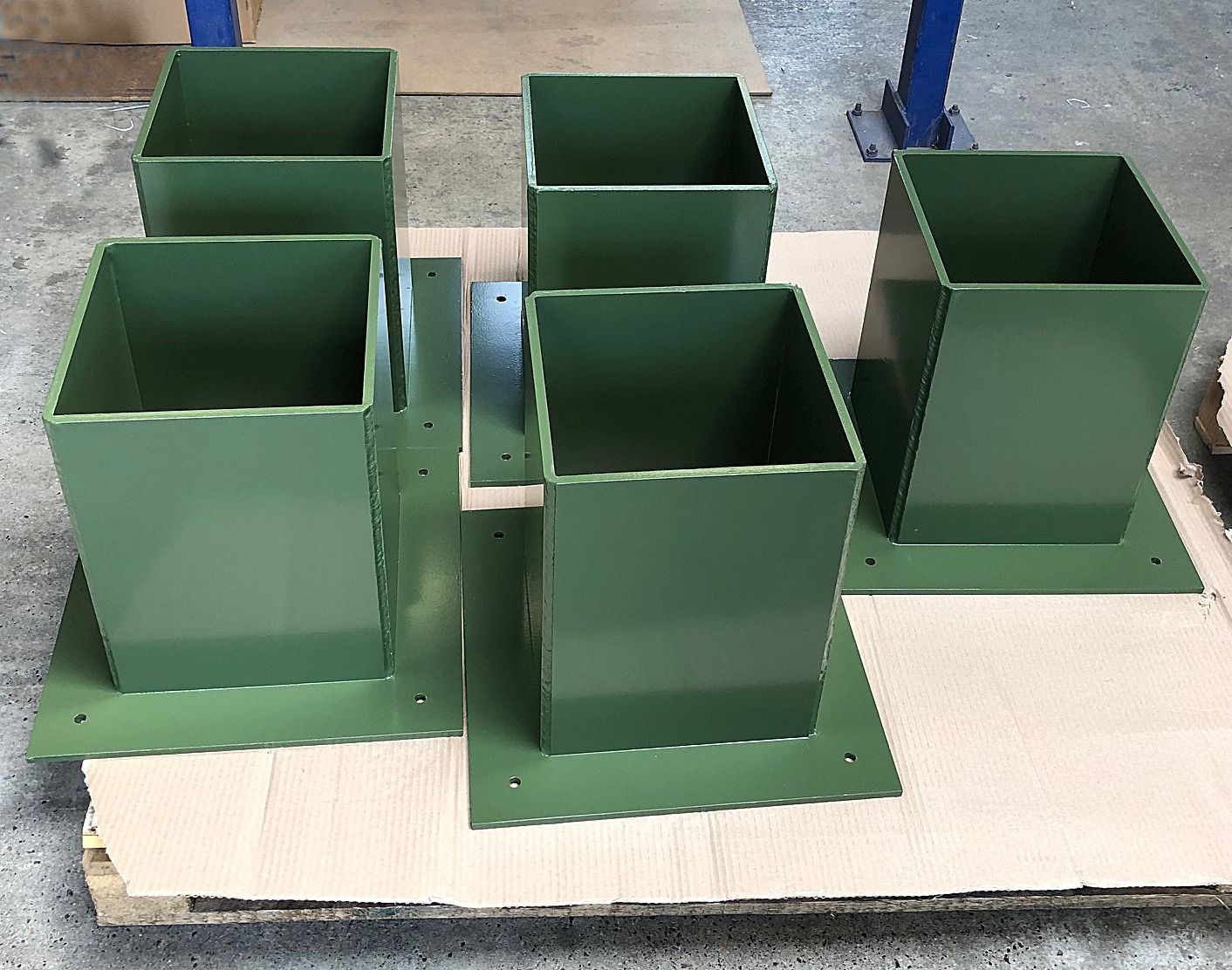

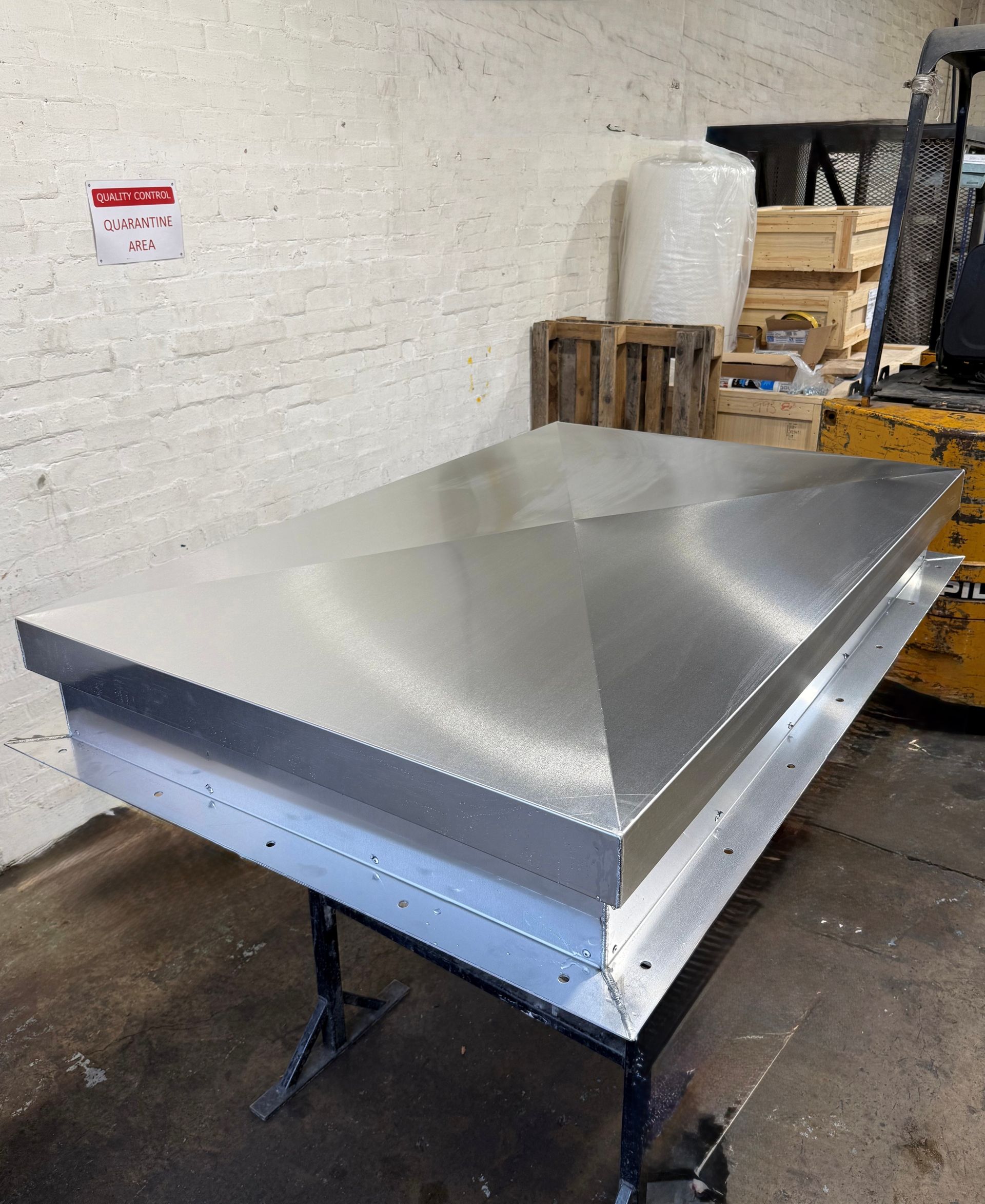

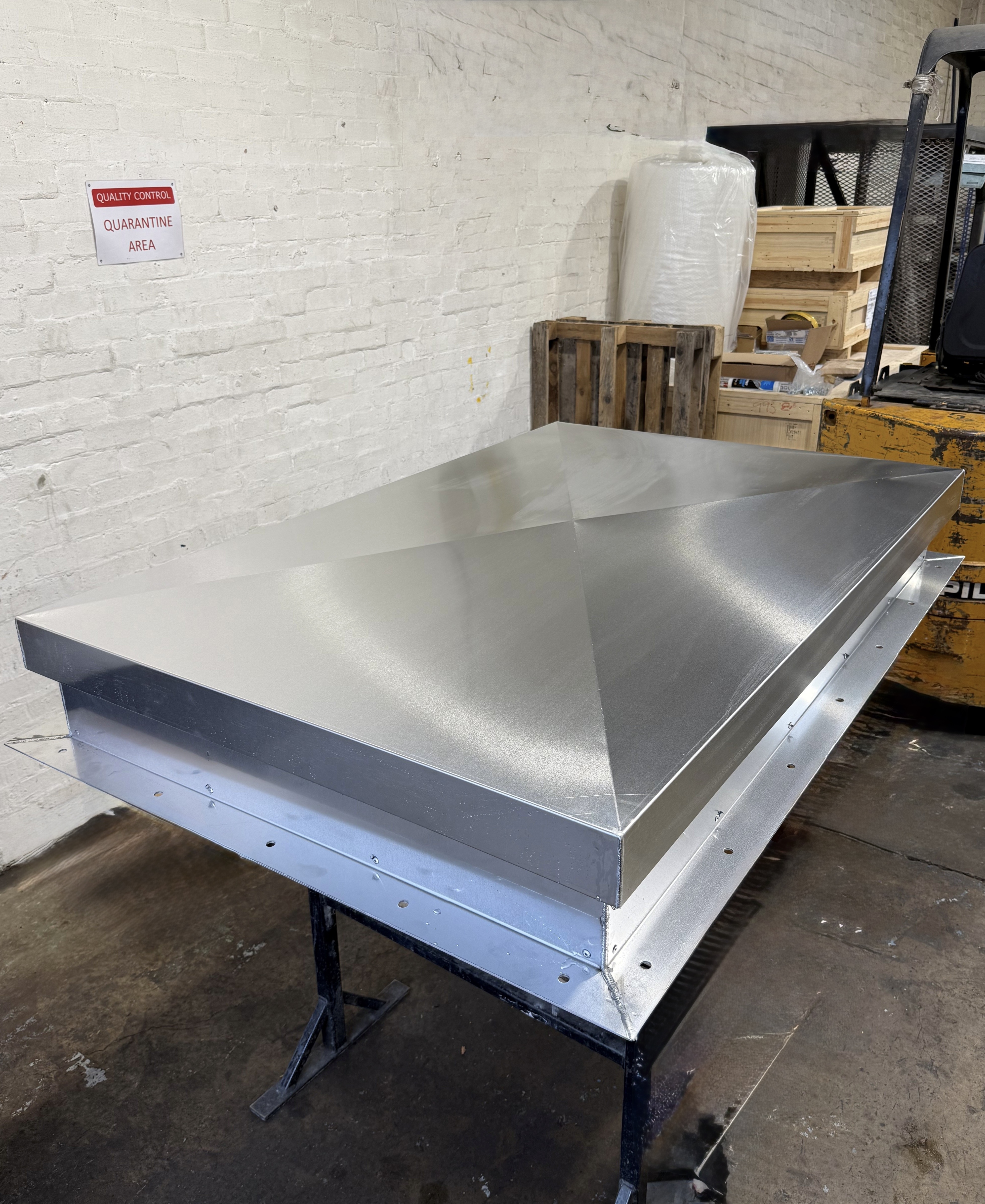

Blast And Ballistic Vents And Louvres

We offer bespoke blast and ballistic venting louvres, panels and vents for a wide range of applications. The purpose of these products is to relieve overpressure within a building and mitigate the impact of the blast.

We manufacture the products ourselves and can therefore accomodate specific requirements, blast release pressures and fixing details. Please click on the download button below for more information on all of our venting products.

DOWNLOAD PRODUCT SELECTION SHEET

FM Approved Products, NFPA And Venting Standards

FM Global / FM Approved

FM Approved products, in the context of blast protection, represent independently tested and certified solutions designed to mitigate the effects of explosive events on buildings and critical infrastructure. Through rigorous evaluation by FM Approvals—an internationally recognized third-party certification body affiliated with FM Global—these products are assessed for their ability to withstand blast pressures, impulse loads, and associated structural demands while maintaining functional integrity. FM Approval provides asset owners, designers, and insurers with confidence that blast-resistant components such as walls, panels, doors, and assemblies meet defined performance criteria for loss prevention and life safety. As a result, FM Approved blast-protection products play a key role in resilient design strategies for high-risk and high-value facilities, supporting both risk reduction and continuity of operations.

FM Approved Explosion Venting Systems – Properties and Function

FM Approved explosion venting systems are engineered assemblies used to protect structures, equipment, and personnel from excessive internal pressures generated by deflagration or explosion events. These systems are designed, tested, and certified to meet stringent performance criteria set by FM Approvals (Factory Mutual), ensuring reliable performance under specified conditions.

Core Properties

Pressure-Activated Release

o Systems are designed to remain secure under normal operating conditions (e.g., wind loads, thermal expansion), but to release at predetermined internal pressure thresholds associated with explosion hazards.

Damage-Limiting Design

o Venting panels are integrated into walls, roofs, or enclosures as intentional weak points in damage-limiting construction (DLC) so that built-up overpressure is directed outward, reducing stress on pressure-resistant elements of a structure.

Reusable Components

o When properly designed and maintained, many FM Approved venting systems can be reset or reused after an event without full replacement, depending on damage severity.

Regulated Release Characteristics

o Approval criteria quantify performance in terms of pressure at which components (fasteners, latches, panels) release, alignment, manufacturing quality assurance, and traceability.

Explosion Venting Fasteners and Washers

Purpose and Role

Fasteners and washers in FM Approved explosion venting systems are specialized mechanical components used to attach vent panels, doors, or roof elements to primary structural framing. They serve two essential functions:

o Secure attachment under routine loads (e.g., wind, vibration, change in temperature)

o Controlled release at designated explosion pressures, allowing vent panels to detach to relieve overpressure without causing unpredictable fragmentation.

Typical Properties

Predetermined Failure Load

o Fasteners and accompanying washers are engineered to collapse or release at specified internal pressures. For example, in FM Approvals guidance, washers with different color-coded release values are used (e.g., 70 lb, 110 lb, 175 lb, and 435 lb per fastener).

Materials and Coatings

o Fasteners often employ corrosion-resistant materials (e.g., galvanized steel) and include bonded EPDM sealing washers to maintain weatherproofing and withstand environmental exposure.

Installation Considerations

o Approved installation requires precise alignment of fasteners and washings, use of specific bolt diameters, and occasionally oversize holes with centering sleeves to ensure correct collapse behaviour.

Panel Integration

o Washers are typically slightly convex and sized to balance secure retention with reliable release characteristics, supporting panel integrity but enabling prompt venting under specified pressures.

Brixon Fully Adjustable Release Latches – Properties and Applications

Brixon fully adjustable release latches are FM Approved explosion venting latches that serve as reliable pressure release mechanisms mounted on doors, access panels, enclosures, ovens, HVAC components, or ductwork where internal overpressure risk exists. Read more here: https://www.brixon.com

Key Functional Properties

Positive Seal in Normal Operation

o Brixon latches maintain a tight seal to prevent heat, gases, or vacuum loss during normal operation.

Adjustable Release Force

o Using simple tools (screwdriver or Allen wrench), the release force can be tuned to a specific threshold that reflects system design requirements—enabling venting activation at intended pressures.

Reusable After Activation

o Unlike rupture disks or fixed panels, Brixon latches typically are not destroyed during venting events; they can be reset by closing the door and re-sealing, offering long-term cost effectiveness.

Material and Finish Options

o Available in a broad range of materials, including stainless steel (high corrosion resistance), cast steel, cast iron, aluminum, spark-proof brass, and other alloys, suitable for varied industrial atmospheres and cleanliness requirements.

Modular Configurations

o Latches can be linked to support higher cumulative release forces (e.g., above 3,000 lb per door), enabling scalability for large enclosure doors.

Typical Applications

Brixon adjustable release latches are widely used where controlled pressure release is critical. Key application areas include:

Industrial Processing Equipment

o Ovens, dryers, autoclaves, coating booths, spray booths where combustible dust, vapours, or gases may accumulate.

Dust Collection Systems

o Cyclones and collectors where combustible particulates could lead to rapid pressure rise.

HVAC and Air Handling

o Ductwork and HVAC access panels requiring controlled venting under abnormal pressure.

Chemical and Manufacturing Facilities

o Enclosures where reactive chemicals are processed, stored, or mixed.

Military, Aviation, and Energy Storage

o Specialized environments with stringent safety thresholds and broad operating conditions.

Food, Beverage, and Pharmaceutical

o Enclosures with regulatory sanitation requirements, benefiting from stainless steel latch options.

Use Cases and Integration Contexts

Integration of FM Approved venting fasteners, washers, and Brixon latches typically occurs in systems that:

o Require predetermined and reliable pressure relief to protect personnel and prevent catastrophic structural damage.

o Need adjustable and testable release mechanisms that can be calibrated, inspected, and maintained over long service lives.

o Must comply with property loss prevention standards such as FM Global Data Sheets and NFPA guidance for explosion and deflagration protection.

In damage-limiting designs, venting panels and associated fasteners are sized and located to ensure the vent area corresponds to anticipated explosion parameters, while adjustable latches on doors and enclosures allow controlled venting without component destruction.

Key FM Approval Standard: Class Number 4440

FM Approvals Standard 4440 (“Explosion Venting Wall Systems Including Fasteners and Latches for Damage Limiting Construction”) defines the performance requirements and criteria for explosion venting systems, including:

o Wall panels and venting assemblies that are secured under normal loads but release at pre-determined pressures.

o Fasteners and latches that hold panels or doors in place and release when a design overpressure is reached.

o Quality assurance, manufacturing, marking, test methods, and FM trial/verification processes for approval.

Important context from the FM standard:

o The scope focuses on damage-limiting construction (DLC) and does not itself prescribe vent sizing or placement guidelines. Rather, it mandates that products perform as intended under design pressure thresholds.

o Designers must refer to FM Global Loss Prevention Data Sheets (e.g., FM 1-44) and other design standards for determining vent area, placement, and structural design criteria.

Explosion Vent Panels – Typical Performance Characteristics

FM Approved vent panels are engineered to relieve pressure within defined design parameters. Specific release pressures of FM Approved products (as an example from a vendor’s FM Approved panel) include:

o EXA-74: 0.625 kPa release per pair of fasteners.

o EXA-76: 0.915 kPa release.

o EXA-79: 1.38 kPa release.

o EXA-84: 3.245 kPa release.

Values increase based on the number and type of fasteners used.

Application notes:

o Vent panels may also include insulation (e.g., 50 mm EPS70) and restraint cables to control panel motion after release.

o The actual release pressure for a given panel depends on panel area and the fasteners’ combined release load.

FM Approved Explosion Venting Fasteners and Washers

Fasteners and washers provide controlled panel release at defined loads. Typical FM Approved components (from FM Approval Class 4440 listings) include:

| Washer Code | Colour | Nominal Diameter | Release Load (lb / N) |

|---|---|---|---|

| EXA-74 | Green | 0.729 in | 70 lb (310 N) |

| EXA-76 | Blue | 0.729 in | 110 lb (490 N) |

| EXA-79 | Tan | 0.729 in | 175 lb (780 N) |

| EXA-84 | Light Green | 0.729 in | 435 lb (1930 N) |

| EXA-19 | Light Blue | 0.729 in | 885 lb (3940 N) |

Design Insight

o Fastener holes through the panel should include a centering sleeve and be oversized so washers remain convex under preload, ensuring predictable release.

Sizing Methodology for Explosion Vent Panels

FM Approval documentation does not itself prescribe vent sizing formulas; however, the FM Global Loss Prevention Data Sheet 1-44 and NFPA standards are typically referenced for design.

Design Standards Used in Engineering Practice

FM Global Loss Prevention Data Sheet 1-44 — Damage Limiting Construction

o Provides guidance on determining vent area relative to expected explosion pressures based on occupancy classification.

o Recommends vent location to avoid snow/ponded water and debris accumulation on roof vents.

o Recommends maximum vent panel weight (e.g., ~3 lb/ft²).

NFPA 68 — Standard on Explosion Protection by Deflagration Venting

o Widely referenced for vent area sizing based on the explosive properties of gases and dusts (e.g., Kst, Pmax).

o Calculation considers vessel volume, mixture properties, panel inertia, and desired allowable pressure (reduced pressure). Design details are in NFPA 68 Chapter 7 and related sections.

Latch Release Force Calculations

For doors and panels held by latches, FM Global property data sheets provide formulas to select minimum latch release forces based on panel area and design overpressure.

Hinged Doors

Formula (per FM Data Sheets for industrial ovens and similar enclosures):

Maximum allowable release force per latch = (A x Pr) / (2 x L)

Where:

o A = Panel area (ft² or m²)

o P_r = Design release pressure (lb/ft² or Pa)

o L

= Number of latches

The factor “2” accounts for hinge restraint reducing latch load.

Unhinged Panels

Formula:

Max release force per latch = (A x Pr) /L

No hinge factor applies.

Industry Standards Supporting Design and Compliance

Primary FM Standards and References

o FM Approval Class 4440 — Defines performance requirements for venting panels, fasteners and latches.

o FM Global Loss Prevention Data Sheet 1-44 — Provides vent placement, area guidance, and installation details.

Complementary Standards

o NFPA 68 – Standard on Explosion Protection by Deflagration Venting — Widely used for vent area sizing and design methodology.

o NFPA 69 – Standard on Explosion Prevention Systems — Covers broader protection system design.

Practical Design Guidance and Engineering Application

Identify Hazard and Design Parameters

o Determine explosive mixture type (gas/dust), Pmax, Kst, enclosure volume, ignition location, and allowable reduced pressure. NFPA 68 provides correlating tables and formulas.

Vent Area Calculation

o Use NFPA 68 (or equivalent method) to calculate required total vent area. FM 1-44 guides vent placement relative to structure.

Select Panel and Fasteners

o Choose FM Approved vent panels and fasteners sized such that panel area × fasteners’ release load equals the target design pressure. Apply FM 4440 principles.

Latch Selection and Adjustment

o Use FM Data Sheet formulas to calculate maximum latch release force per unit based on area and design pressure. Compare to manufacturer’s FM Approved release forces.

Installation and Quality Assurance

o Fit centering sleeves and washers correctly. Follow FM Approved product installation instructions and include restraint methods (e.g., cables) where required.

NFPA 68 is the core industry standard governing vent area sizing and vent design methodology for combustible dust and gas deflagrations. It defines mandatory requirements and design equations. Key clause references include:

Chapter 6 — General Design Requirements:

This covers vent selection, installation, location, and mechanics, including the influence of panel inertia, static opening pressure (Pstat), and mounted orientation.

Clause 8.2.1 & 8.2.2 — Vent Area Equations:

These present the basic sizing equations for full-volume vent area (Av1) and partial-volume vent area (Av4), including input parameters such as Pmax, Kst, vessel volume, and Pred (reduced pressure).

Annex A Example Calculations (e.g., A.8.4.2b):

NFPA provides worked examples showing how to solve vent area for given process parameters and how to iterate to find Pred for specified Av.

To obtain the most current clauses and normative text, access NFPA 68 directly via the NFPA webstore or your standards subscription service.

FM Global Loss Prevention Data Sheet 1-44 — Damage-Limiting Construction

FM 1-44 provides practical construction guidance for building structures and pressure-relieving vent panels used in damage-limiting construction (DLC), including:

Section 2.1.4 – Pressure-Relieving Vent Panels:

Guidance on placement, spacing, orientation, and load limits for explosion relief vents used in building envelopes.FM

Section 2.1.6 – Guidelines for Determining DLC Design Criteria:

Explains how to establish design criteria for specific occupancy hazards (fuel reactivity groups).FM

You should consult FM 1-44 when designing vent panels integrated with structural walls and roofs, particularly for industrial buildings and damage-limiting performance objectives.

Explosion Vent Sizing Calculation Worksheets

Below are practical worksheet templates based on NFPA 68 prescriptive methods. You can place these into Excel or engineering tools to compute vent area iteratively.

Basic Vent Area Calculation (Dust or Gas Enclosure)

INPUTS (known parameters)

| Variable | Symbol | Unit |

|---|---|---|

| Vessel / Enclosure Volume | V | m³ |

| Maximum Explosion Pressure | Pmax | bar (guage) |

| Deflagration Index (dust) or laminar burning velocity (gas) | Kst / Su | bar m/s or m/s |

| Target Reduced Pressure | Pred | bar (guage) |

| Static Opening Pressure (Vent) | Pstat | bar (guage) |

Step 1 — Apply NFPA 68 Vent Area Equation

Use the NFPA equation form for full-volume venting:

Av = f(V, Kst, Pmax, Pred, Pstat)

Placeholders for the specific NFPA formula expressions (A.8.2.1 and A.8.2.2) vary by mixture type and geometry.

Step 2 — Calculate Required Vent Area

Compute vent area iteratively:

o Iterate on Av until resulting Pred from NFPA equations converges to your design Pred.

o For gas mixtures, include inertia corrections where applicable.

OUTPUT:

o Required Av (m² or ft²)

o Resulting Pred (bar or psi)

Use these results to select FM Approved vent panels that provide at least this net vent area and open at or below the defined Pstat.

Adjusted Vent Area for Practical Panel Mass and Inertia

INPUTS

All values from Worksheet A plus:

o Panel mass per unit area (kg/m²)

o Loss coefficients for duct/deflector arrangement

Step 1 — Apply Inertia Adjustment Factor

NFPA requires accounting for panel mass and installation inertia which increases required Av. This is typically handled in design curves or iterative calculations as per Clause 8 of NFPA 68.

WORKFLOW

1. Use initial calculated Av from Worksheet A.

2. Apply inertia correction factor (function of panel mass and geometry).

3. Recompute Pred and adjust Av if needed.

OUTPUT:

o Adjusted vent panel area

o Required number/size of panels

FM Data Sheet 1-44 Vent Panel Area (Building Enclosure)

INPUTS

o Building footprint and elevation area (m²)

o Hazard occupancy category (fuel reactivity/combustible concentration)

o Local wind loads

Step 1 — Determine Required Vent Relief Area

Refer to FM 1-44 Table and criteria for the percentage of wall/roof area that must be vented.FM

OUTPUT:

o Vent relief area as % of building area

o Fastener/washers selection that achieve that release target pressure

Examples of Filled Calculation Template Snippets

Below are simplified examples to illustrate how inputs flow through NFPA equations (note: actual NFPA calculation includes nonlinear terms and iterative solutions):

Example — Dust Collector Vent Area (simplified)

| Parameter | Value |

|---|---|

| V (volume) | 10 m³ |

| Kst | 200 bar m/s |

| Pmax | 8 bar (g) |

| Pred target | 0.5 bar (g) |

| Pstat (vent) | 0.05 bar(g) |

Compute Av required using NFPA 68 Equation from Clause 8.2:

Approx Av = (V2/3 x Kst) / (C x (Pmax - Pred) )

(C is a coefficient in NFPA formula.)

Result:

o Required vent area ~1.2 m²

(This matches sample tabulated case in NFPA Annex A example.)

Panels would be selected with individual areas that sum ≥1.2 m² and static opening at ~0.05 bar.

References & Where to Obtain Exact Clauses

You can obtain the full normative text from the standards bodies:

o NFPA 68 — Standard on Explosion Protection by Deflagration Venting (latest edition). Available from NFPA webstore. nfpa.org

o FM Global Loss Prevention Data Sheet 1-44 — Damage-Limiting Construction. Available directly from FM’s document portal. FM

Latch Release Forces (FM Data Sheet–based) tab

o Hinged-door latch sizing based on FM Global guidance

Inputs:

o Door or panel area

o Design release pressure

o Number of latches

Embedded formula:

F = (A x Pr) / (2 x L)

Output:

o Maximum allowable release force per latch

o Directly compatible with FM Approved adjustable latches (e.g., Brixon)

This tab supports doors, access panels, ovens, dryers, and equipment enclosures.

Assumptions & References

Clear statement of engineering assumptions

Explicit reference to:

o NFPA 68

o FM Global Loss Prevention Data Sheet 1-44

o FM Approval Standard 4440

NFPA 68 - Further Information

NFPA 68 – Standard on Explosion Protection by Deflagration Venting

1. What NFPA 68 Is

2. NFPA 68 is a consensus safety standard published by the National Fire Protection Association.

It provides requirements and guidance for protecting equipment, buildings, and enclosures from deflagration explosions through the use of explosion venting.

Purpose of the Standard

To reduce structural damage and risk to life when a combustible dust, gas, mist, or vapor deflagration occurs. It does this by establishing methods to safely relieve pressure generated during an explosion.

Scope and Applicability

Applies to enclosed systems such as:

o Process equipment (e.g., dust collectors, silos, mixers)

o Industrial buildings and rooms

o Covers deflagrations involving:

o Combustible dusts

o Flammable gases and vapors

o Hybrid mixtures

o Does not address detonations or explosion prevention methods.

Basic Principle of Deflagration Venting

Explosion venting works by allowing pressure to escape through a designed opening before structural failure occurs. Properly sized and located vents limit internal pressure to a level the enclosure can withstand.

Key Technical Concepts

o Maximum explosion pressure (Pmax)

o Deflagration index (K-value)

o Reduced explosion pressure (Pred)

o Vent area sizing and vent duct effects

Relationship to Other NFPA Standards

Commonly used alongside standards such as NFPA 69 (Explosion Prevention Systems) and NFPA 652 (Combustible Dust Fundamentals). NFPA 68 focuses specifically on protection, not hazard elimination.

Importance in Industrial Safety

Widely used in manufacturing, chemical processing, food production, and material handling industries. Helps engineers and safety professionals design systems that meet regulatory and insurance expectations.

Association Between NFPA 68 and FM Approved Blast Release Products.

Role of NFPA 68

NFPA 68 establishes the design methodology and performance requirements for explosion protection by deflagration venting. It defines how explosion vents must function to safely relieve pressure and limit the reduced explosion pressure (Pred) inside an enclosure. NFPA 68 does not certify or approve specific products; instead, it provides the engineering criteria used to size and apply them correctly.

What FM Approved Blast Release Products Are

FM Approved blast release products (such as explosion vent panels, roof vents or doors) are devices that have been tested and certified by FM Approvals, a third-party testing and certification organization.FM Approval indicates that a product meets specific performance, reliability, and safety criteria under controlled test conditions, including:

o Opening pressure (Pstat)

o Venting efficiency

o Structural integrity

o Repeatability and durability

How the Two Work Together

NFPA 68 provides the calculation and application requirements (e.g., required vent area, Pred limits, vent placement). FM Approved products provide verified hardware that can be used to meet those NFPA 68 requirements.

In practice:

Engineers size explosion vents using NFPA 68 equations and guidance, then select FM Approved vent panels whose tested performance aligns with the calculated needs.

Performance Alignment

FM testing evaluates whether blast release products open as intended during a deflagration and relieve pressure effectively. These performance characteristics directly support NFPA 68 goals, such as:

o Controlled pressure relief

o Predictable vent opening behavior

o Limiting damage to enclosures and surrounding areas

Regulatory and Insurance Acceptance

Many authorities having jurisdiction (AHJs) and insurance providers recognize:

o NFPA 68 as the governing standard for explosion vent design

o FM Approval as evidence of product reliability and compliance

Using FM Approved products can simplify approval, inspection, and insurance review when designing systems in accordance with NFPA 68.

Practical Application in Industry

In industrial facilities, NFPA 68 often drives the engineering design, while FM Approved blast release products are selected to implement that design safely. This combination helps ensure that explosion venting systems are both theoretically sound and proven in real-world testing.

Key Distinction

NFPA 68 = Standard (design and performance criteria)

FM Approved products = Certified equipment (tested solutions)

Compliance with NFPA 68 is achieved through proper design and installation, often supported by the use of FM Approved venting devices.