Protective And Impact Canopies And Enclosures

Protection / Impact Canopies And Enclosures Methodology

Mitigating the effects of explosions and subsequent fragmentation can be both difficult and challenging. Ballistic projectiles generally travel at speeds of around 450 metres per second to 950 metres per second. In terms of mass, bullets are in the region of around 200 to 300 grams.

When we look at protective enclosures, they serve the purpose of protecting people and infrastructure from injury and catastrophic failure. There are important factors to consider here. Penetration potential of the object and kinetic energy. ½ mass x velocity² is the equation for kinetic energy. In terms of bullets, for a commonly used NATO 7.62 round that is about 3,000 Joules or higher.

When dealing with moving parts that weigh many more times the weight of a bullet and travelling at considerably higher velocities the increase in kinetic energy is enormous.

In terms of specialist equipment such as jet engines, then as an example, an object breaking free from its operating parameters could easily generate kinetic energy going into the millions of Joules. Although that level of fragmentation may not have the same shaped penetrative effect of a bullet, the kinetic energy alone is enough to penetrate even armoured steel.

But equally important is the potential of a large object falling under the effect of gravity. So as can be outlined from these examples both mass and velocity combined produce considerable risk to people and the surrounding environment.

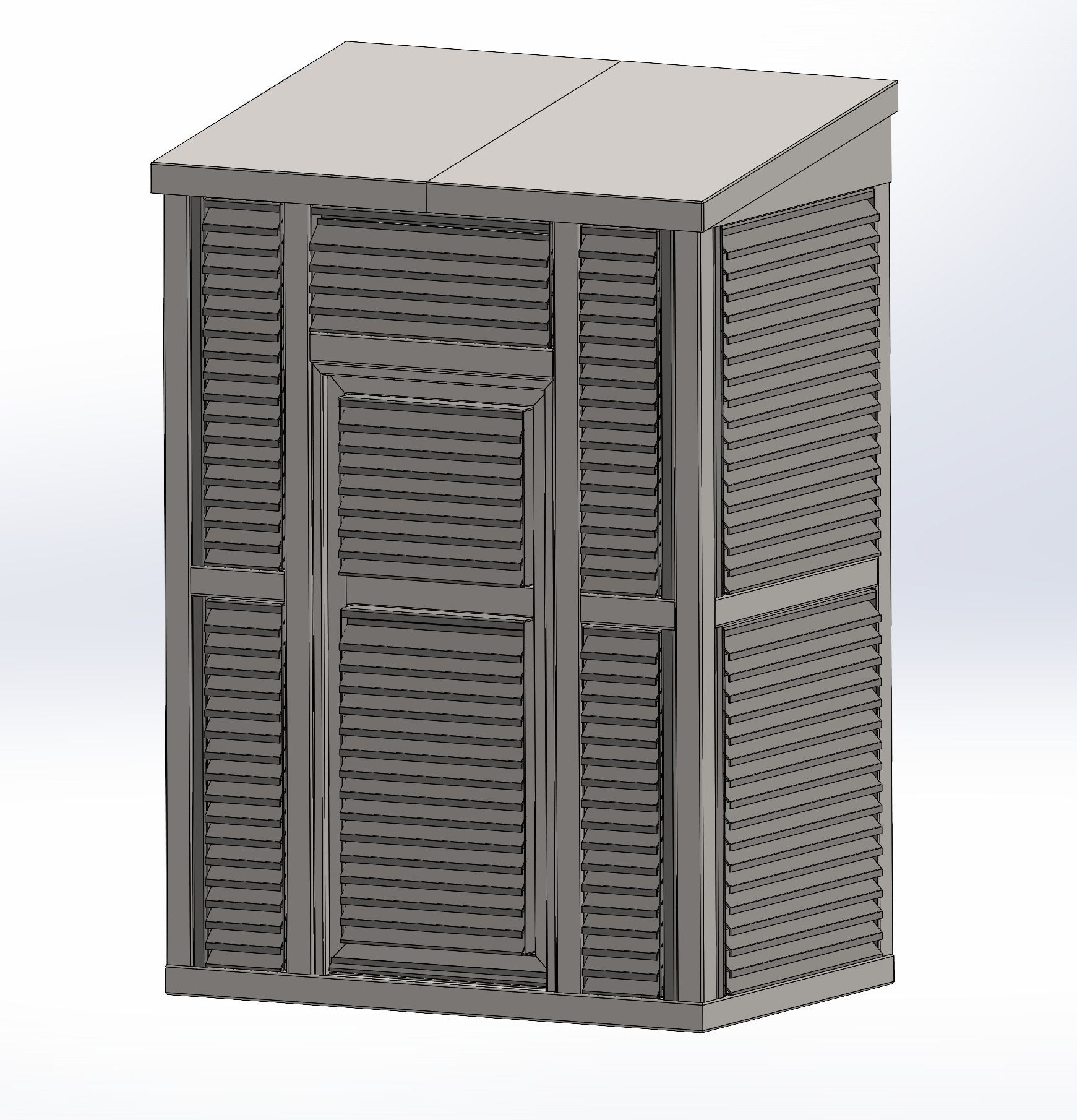

Highlighted here are examples of where various combinations of mass, velocity and penetration (also derived from fragmentation) challenge us in different ways. A protective canopy, within which an operative is working, is subject to the potential of a high voltage insulator weight nearly 90kgs falling from around 20 metres. The roof panel and supporting assembly needs to mitigate this and the roof detail in particular needs to deform no more that 100mm to avoid the potential of injury to the operative inside as the roof panel itself begins to collapse.

We can also see how a louvered blast shelter is housing gas bottles. Although the free airflow provided by the blast louvres mitigates the potential of a build up of gas to some extent and therefore a subsequent explosion, things can still go wrong and a detonation in this situation easily produces velocities in the region of up to 2,000m/s and even higher. Add to that the potential of gas cylinder fragmentation hitting the enclosure, it is easy to see how this product requires a high level of inherent protection.

Velocities produced by turbines or similar equipment produce speeds in the region of tens of thousands of revolutions per minute. Fragments of debris moving at these speeds produce very high levels of kinetic energy with potential penetrative effects.

Some factors influencing the potential threat or hazard:

o Velocity of the moving object

o Mass of the object

o Shape of the object

o Hardness of the object

Some factors influencing the protective structure:

o Hardness of the material

o Ductility of the material

o Thickness of the material

How protective canopies and shelters respond during an incident

A combination of some of the above factors all have a direct result on the performance of the protective canopy or shelter. The over engineering of a solution by using trial and error and perhaps a piece of material that is unwieldly and very thick may provide a theoretical solution, but in reality it is important to assess the risk and mitigate the problem with a carefully engineered solution.

Hard materials with little ductility may stop an object but the consequence of that might be that the object then bounces around and the problem is moved on somewhere else and not mitigated. The energy that is put into a hard piece of material in such circumstances has to be dissipated somewhere and one of those options is for it to transfer the load through the fixings and in to something else which may or may not have been considered to be part of the solution.

Materials that are ductile can absorb energy and move with it. Similar to a spring when absorbing a sudden load. But too much movement can then put the material into a plastic state and cause deformation making it unsuitable for a repeat operation.

From a commercial standpoint it may be more cost effective to have materials that are a ‘one time’ form of protection and then simply change them out in readiness for the next operation. There is also the consideration that should a machine begin to break up then there could be multiple threats arising all at the same time. Again careful consideration is needed to properly address the potential hazard or threat.

Proving the solution

There are basically three ways in which this can be done:

Firstly using empirical data, whereby previous testing can used to provide a solution is always a best option.

Secondly, further testing is also just as beneficial.

Finally, without either of these options, we use established calculations based on material properties and responses that have been previously derived, defined and mathematically supported.

Safety factors are always built into calculations and to some extent are slightly over engineered. In practice, dynamic testing can offer solutions that are more commercially attractive than calculated solutions but in doing that there is then the initial cost of testing and that can run into many thousands of pounds and potentially unattractive for one off products.

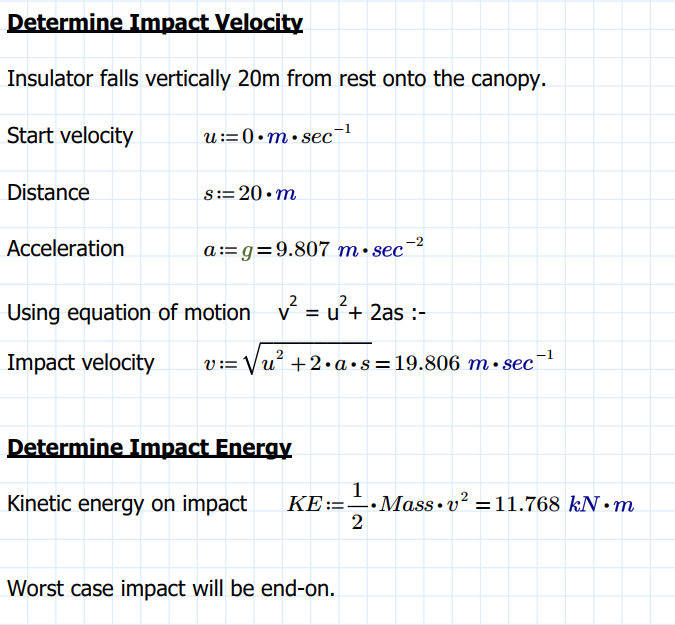

Worked example

Shown above is a protective canopy that is used across the UK in high voltage areas where there is a risk of a 90kg object falling from 20 metres above the ground. The solution has been engineered so that the roof of the canopy has enough ductility to absorb the load yet is hard enough to prevent penetration at the same time. It also provides a pre determined level of collapse so that the roof panel does not yield so much that it then moves down under deformation and hits the operative inside.

Below is a typical extract of how the threat can be determined:

Our broad experience in the fields of Blast and Ballistic protection and manufacturing is of particular value as we are then able to take the data that is produced and convert this into a solution that is workable, practical and commercially viable. The ideal solution to a problem is one that encompasses all of these elements and not one whereby it works on paper but is too practically and commercially challenging to adopt.