Fixed Blast Louvres

DOWNLOAD TECHNICAL DATA SHEET

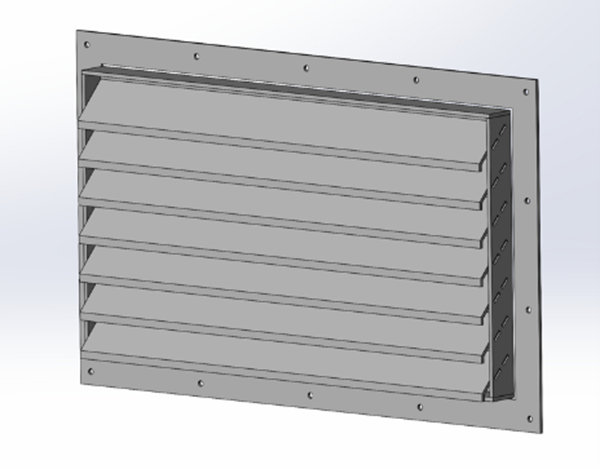

Fixed Blast Louvres

- Blast Louvres are manufactured to allow the free passage of air throughout buildings.

- This is a bespoke product and can be manufactured to meet customer's required dimensions, blast resistance and wall construction/fixing detail.

- They are built so as not to break apart when subjected to a blast load. If a standard louvre collapsed under a blast load, there would be serious risk of injury to people and damage to property. Blast Louvres are intended to prevent that from happening.

- The louvres can also protect against fragmentation if required; depending on the blast, there may be a chance that fragments.

- Blast louvres are primarily used in commercial and military environments.

Product Description

The product is bespoke and manufactured to withstand a large range of blast pressures. The product is intended to allow the free passage throughout buildings, but in the event of a blast, does not break apart. The Louvres are typically required where machinery and equipment requires continuous air flow but have the potential to cause a blast. The Blast Louvres accomodate this air flow requirements whilst also offering protection in the event of an explosion.

Advantages

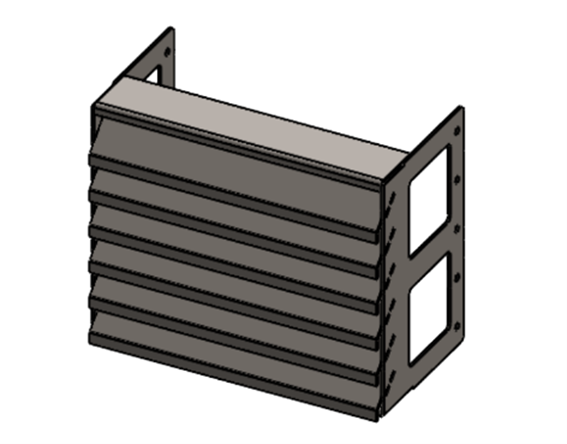

The Blast Louvre can also be combined and is compatible with Blast Ducting/Dampers in order to provide a complete package for a project.

Each unit is bespoke and made to order with the required fixing hole positions and fixing details which allows it to be used in conjunction with other non-blast and blast-rated products to provide a holistic solution.

Features

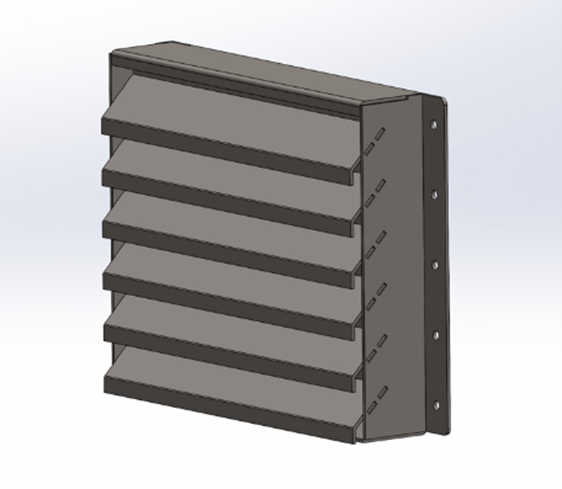

- Available in a factory PPC Finish, Mill Finish and Galvanised.

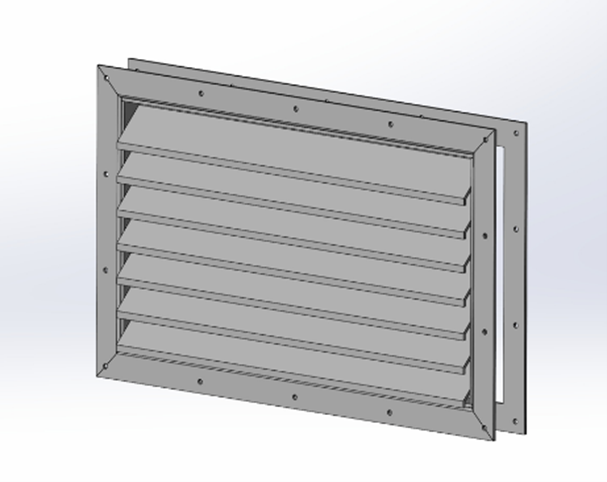

- Can be used for both internal and external applications, installed into walls, panels and doors.

- Can be installed into recess or face mounted with flange.

Protecting A Diverse Range Of Industries

When it comes to industries that face the threat of internal explosions, the list is surprisingly diverse. Our Fixed Blast Louvres are applicable in various sectors, including the petroleum industry, energy and mining, and even brewery facilities. This wide applicability makes it an essential safety measure across different operational setups.

Automotive plants, co-generation facilities, and lithium battery storage areas also greatly benefit from our Blast Louvres. In environments where safety is paramount, such as hospitals and university laboratories, our vents offer that extra layer of protection that could also be the difference between total collapse and business continuity. This explosion protection helps to mitigate damage to businesses and organisations so that they can get back to operational capacity as quickly as possible.

| PROFILE |

|---|

| Folded or drawn steel profiles |

| Available in Steel and Stainless Steel |

| Minimum frame depth/wall thickness 100mm |

| FINISHES |

|---|

| Factory Polyester Powder Coat (PPC) finish |

| Mill Finish |

| Galvanised |

| AVAILABLE SIZES |

|---|

| Minimum 200mm width x 200mm height |

| No maximum single pane size but suggest <1.5m2 due to weight |

| With additional units - indefinite |

| WEIGHTS |

|---|

| Varies with blast resistance required but minimum 25kg/m2 |

| STANDARDS & CALCULATIONS |

|---|

| Each unit has supporting independent third-party calculations available upon request |

| BLAST RATINGS |

|---|

| Individually calculated to meet and exceed required blast ratings |

| Intended to protect against fragmentation if required |

| OPTIONS |

|---|

| Further structural frameworks to support specific wall apertures and applications |

| Fragmentation protection option available |

| FIXING HOLE POSITIONS |

|---|

| Fixing hole positions can be adjusted to suit different wall depths and thicknesses |

| SHIPPING |

|---|

| Supplied in International Shipping Crates for dispatch |

Typical Areas of Application

· Chemical Production

· Petroleum Industry

· Paint, Varnish Manufacturers

· Energy/ Mining Industry

· Co-Generation Plants

· Recycling Centres

· Sewage Treatment (by-product recycling)

· Automotive (air bag, mfg. Plant lines)

· Grinding/Pulverizing processes (airborne dusts)

· Ink Manufacturers

· Energy Storage Systems (ESS)

· Industrial Processing Equipment

· Paper Process (solvent use/storage)

· Laboratory Test Facilities

· Hospitals (gas and/or flammable storage areas)

· Brewery Facilities (grain storage/processing)

· Fossil Fuel Plants (coal dusts)

· Food Processing (airborne dust)

· University Labs (chemical lab store rooms)

· Grain Milling Facilities (airborne dusts)

· Nuclear Power Stations

· Printing Companies (solvent use/storage)

· Gas/Vapour Handling Equipment

· Dust Collection Systems

Fragmentation Protection Option

Protection from fragmentation is also necessary in certain applications. This can include such operations as ammunition manufacturing.

In this instance, the blast louvre will also need to accomodate fragments or shrapnel that can be travelling up to as much as 3,000m/s. In mitigating this resistance, we incorporate our ballistic technology to produce a system that offers both blast resistance, bullet resistance and hence fragmentation resistance.

This product is available in all sizes in galvanised or factory PPC finish. This unit is purpose made as with all of our products. In terms of installation, these units can be reveal or surface mount fix.

They are suitable for both indoor and outdoor applications and work in both directions.

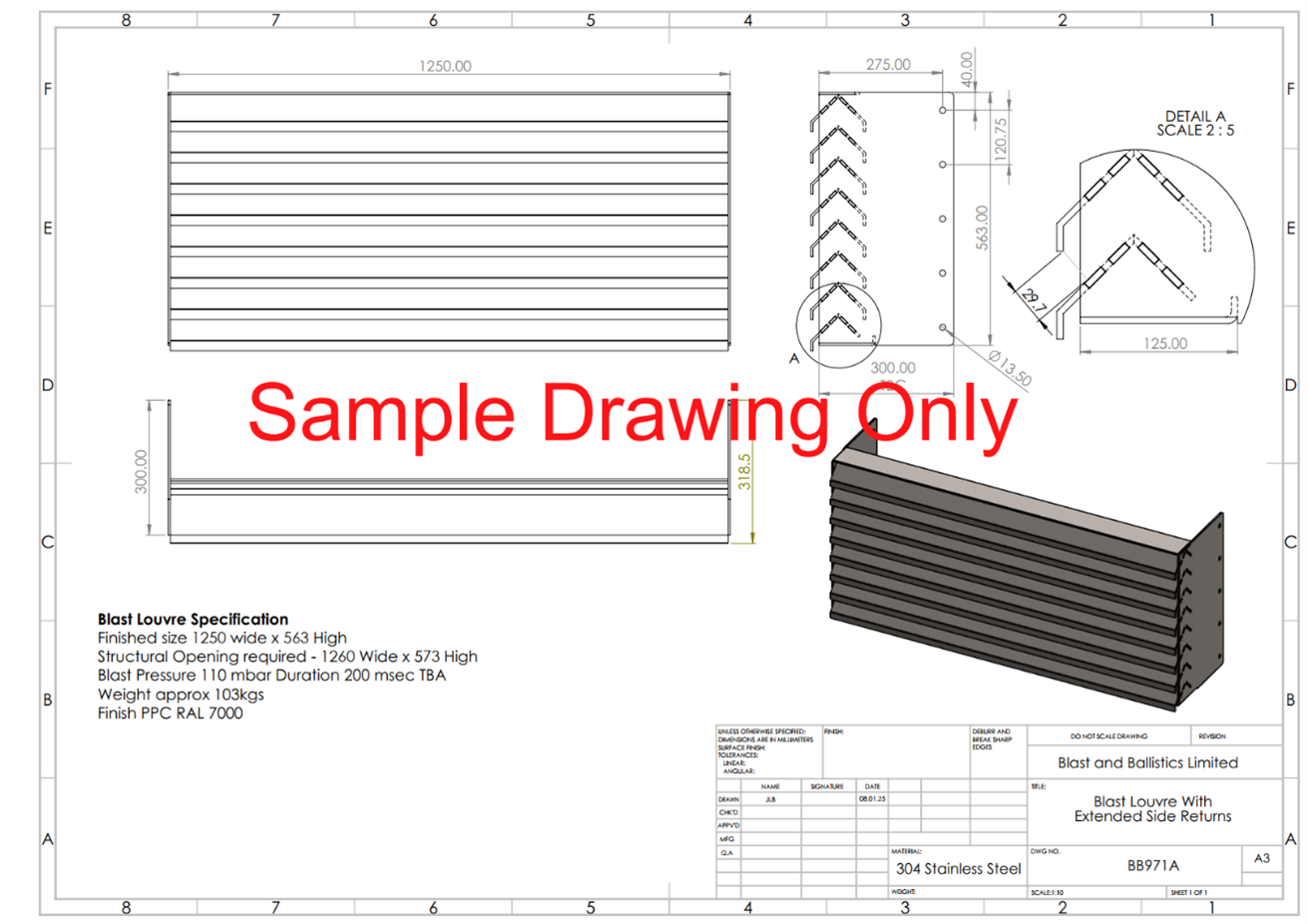

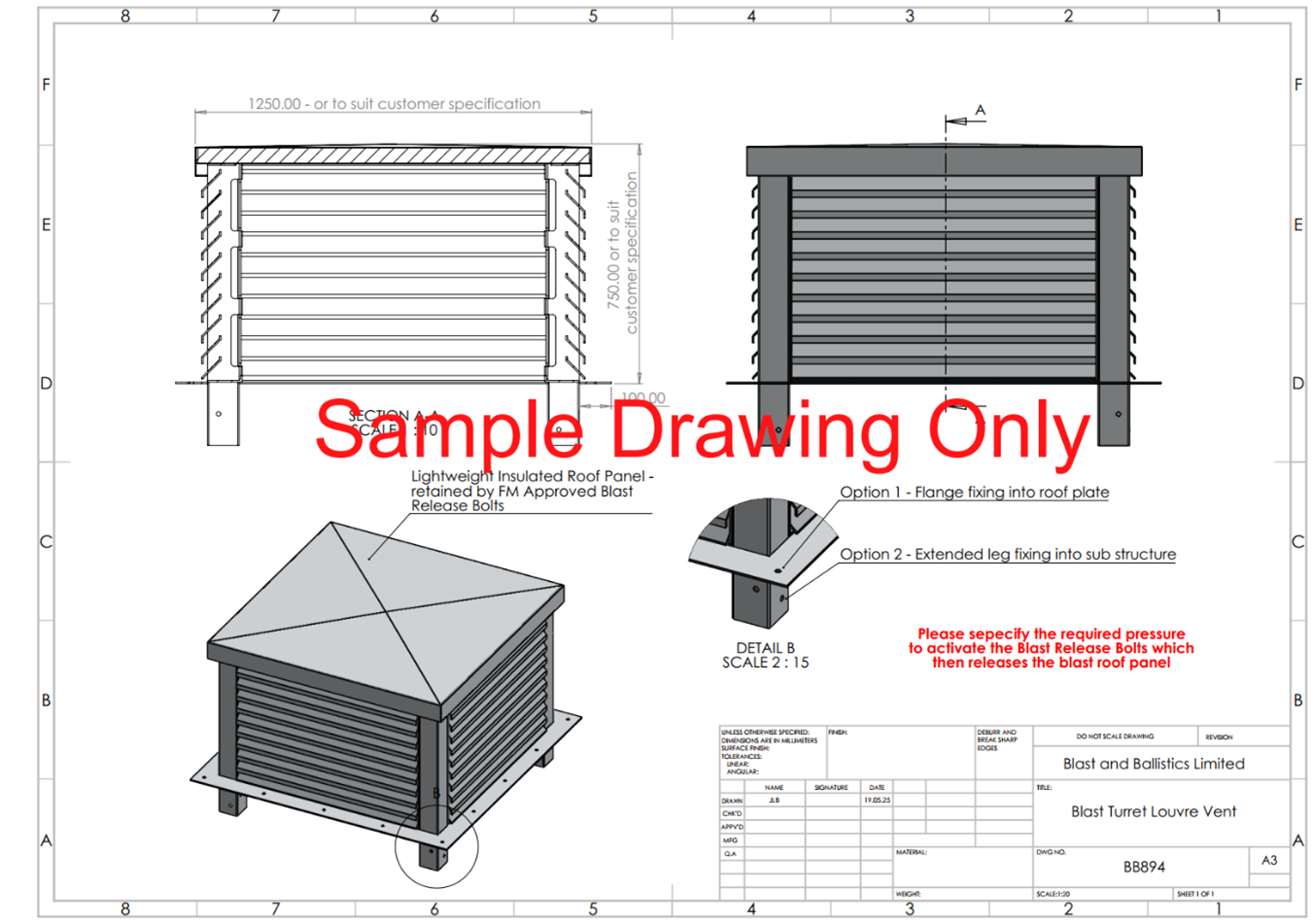

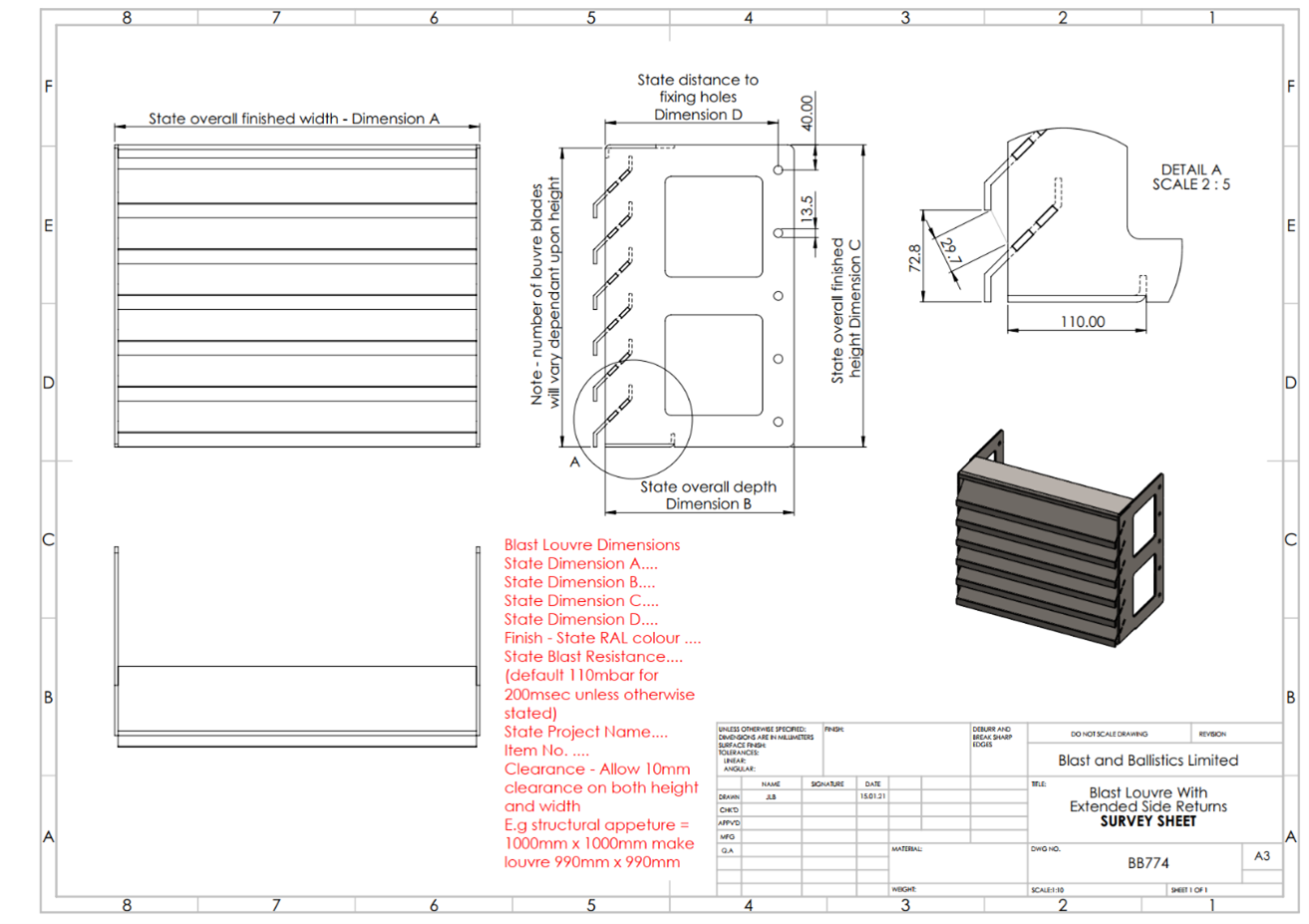

Survey Sheets

We offer standard templated drawings to help assist customers during the intial phase of a project.

Full drawings are always provided prior to manufacture.

Manufacturing Process & Shipping

Project-Specific Calculations

The product range has undergone significant testing and calculations which can be provided upon request.

Project-specific calculations can also be produced, crucial for compliance with Health and Safety regulations.

The calculations are approved by a third-party independent blast consultant.

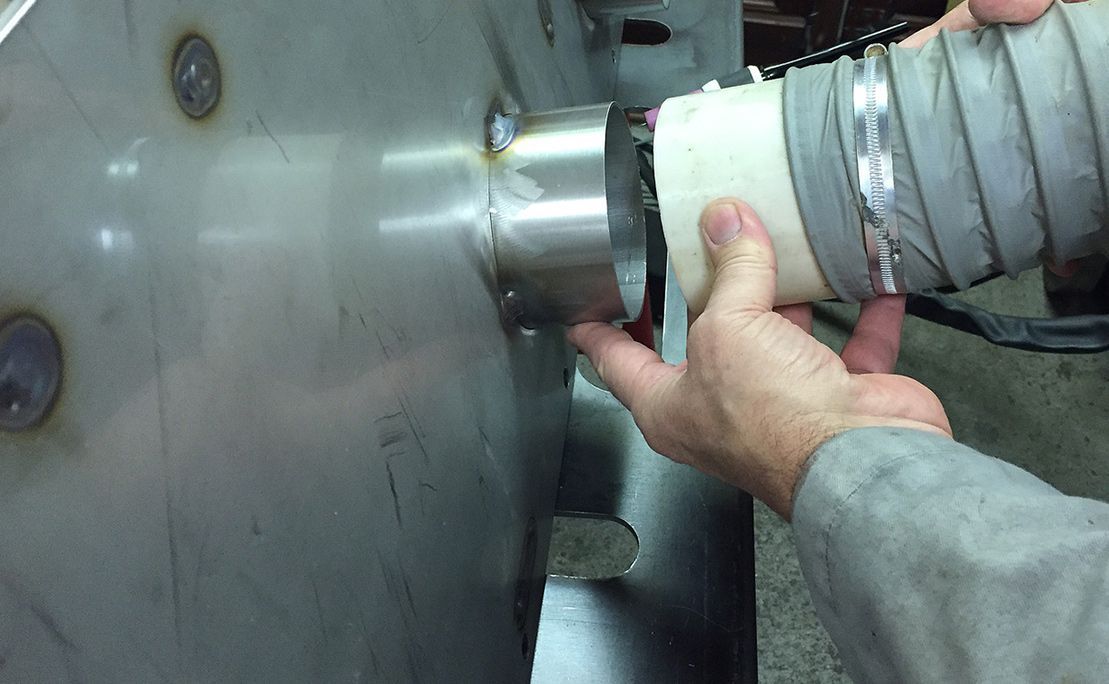

Blast Louvres are available with inlet and exhaust holes for connection to Air Control Systems

Manufacture Images

Fixing Detail Options

Frequently Asked Questions

What level of blast resistance can you achieve?

We can accomodate a wide range of static and dynamic blast pressures.

Each unit is bespoke and manufactured to the required blast resistance.

Please get in touch with us to discuss your specific project requirements.

Where are Blast Louvres required?

Typically, Blast Louvres are required in Data Centres, Power Plants, Government and Healthcare facilities.

Blast Louvres allow for the free passage of air however following an explosion or blast, does not become a threat itself by breaking apart or becoming a projectile.

What materials are the units constructed of?

The construction of the unit is dependent upon the blast resistance requirement and dimensions of the louvre.

Each unit is bespoke and made to order, taking into account the required blast resistance, location, dimensions and wall construction.

Typically, the units are manufactured from heavily profiled steel and stainless steel.

The units are then have a factory PPC finish as standard, Mill Finish or Galvanised Finish as required.