Frangible Explosion Blow Out / Rupture Panels And Safety Cages

DOWNLOAD TECHNICAL DATA SHEET

- Manufactured from Super Lightweight GRP faced insulated materials.

- The product is available in a range of RAL colours, special finishes on request

- Available in both standard and also Fire Rated constructions.

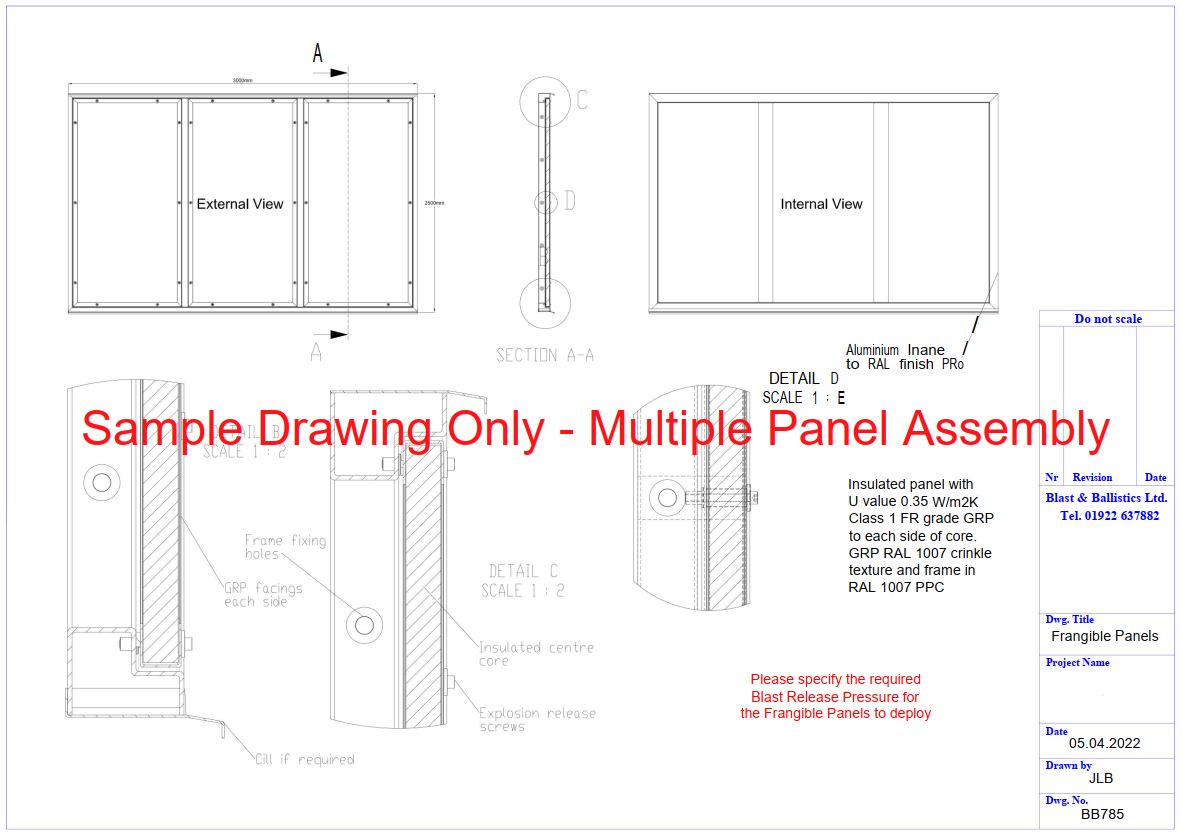

- The panel is retained by FM Approved Blast Release Bolts which provide a wide range of release values to accomodate all sizes of frangible panels and specified release pressures.

- The panel is released into a safe area in response to an internal blast or explosion.

- Frangible Blow Out / Rupture Panels provide the most efficient method of releasling overpressure from a blast or explosion.

Product Description

The centre panel is manufactured from Super Lightweight GRP material which in the event of a blast, will release at the customer’s chosen blast pressure, in order to release overpressure from the building. We use an FM Approved Blast Release Mechanism which is made to ensure an accurate and consistent release.

Read more here: https://www.fm.com/uk/about-us/our-organization/approvals

Advantages

The unit provides instant pressure relief over larger areas than what can be achieved with other vent products. This is suitable for both small and large threats that may arise in factories and processing plants.

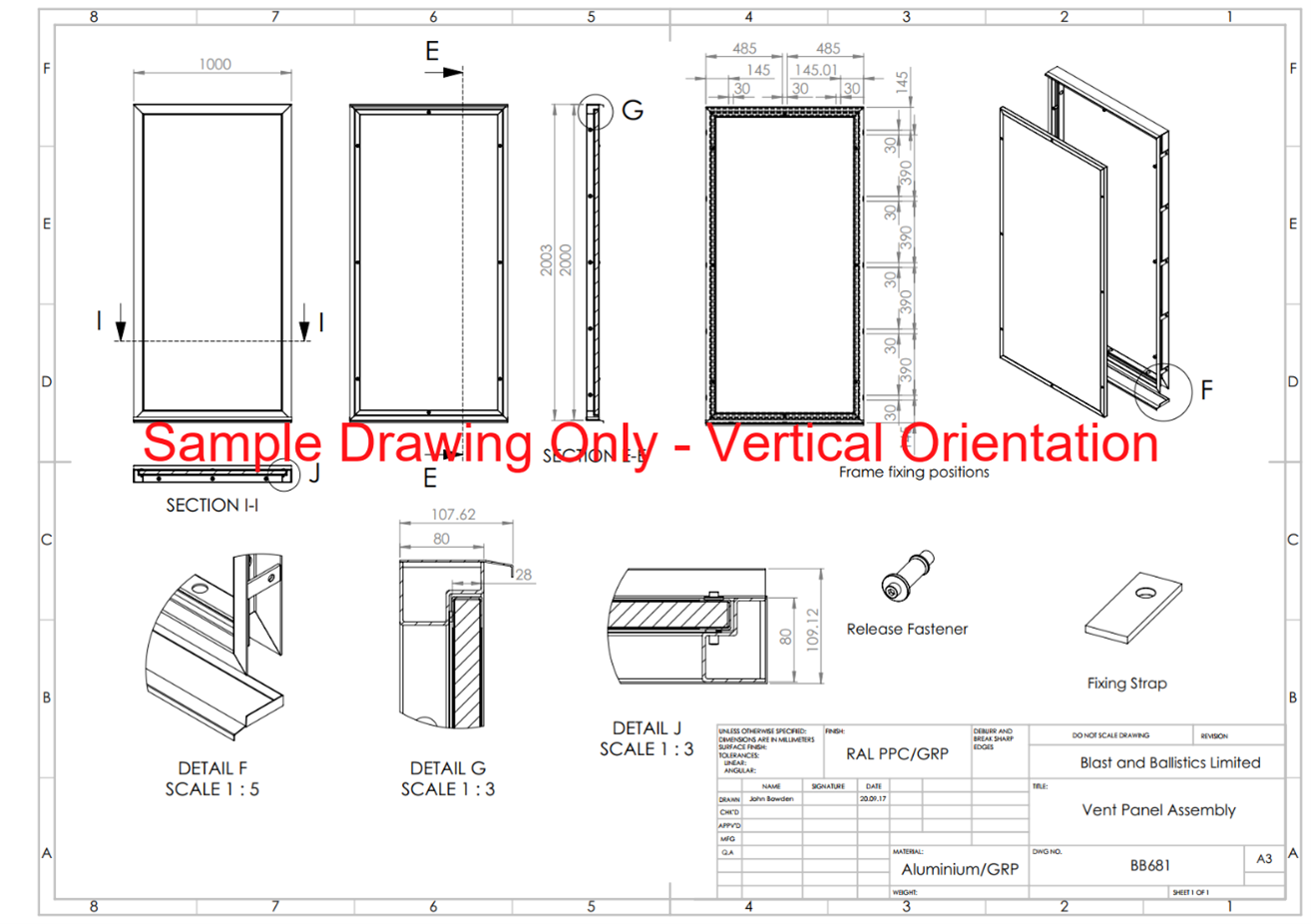

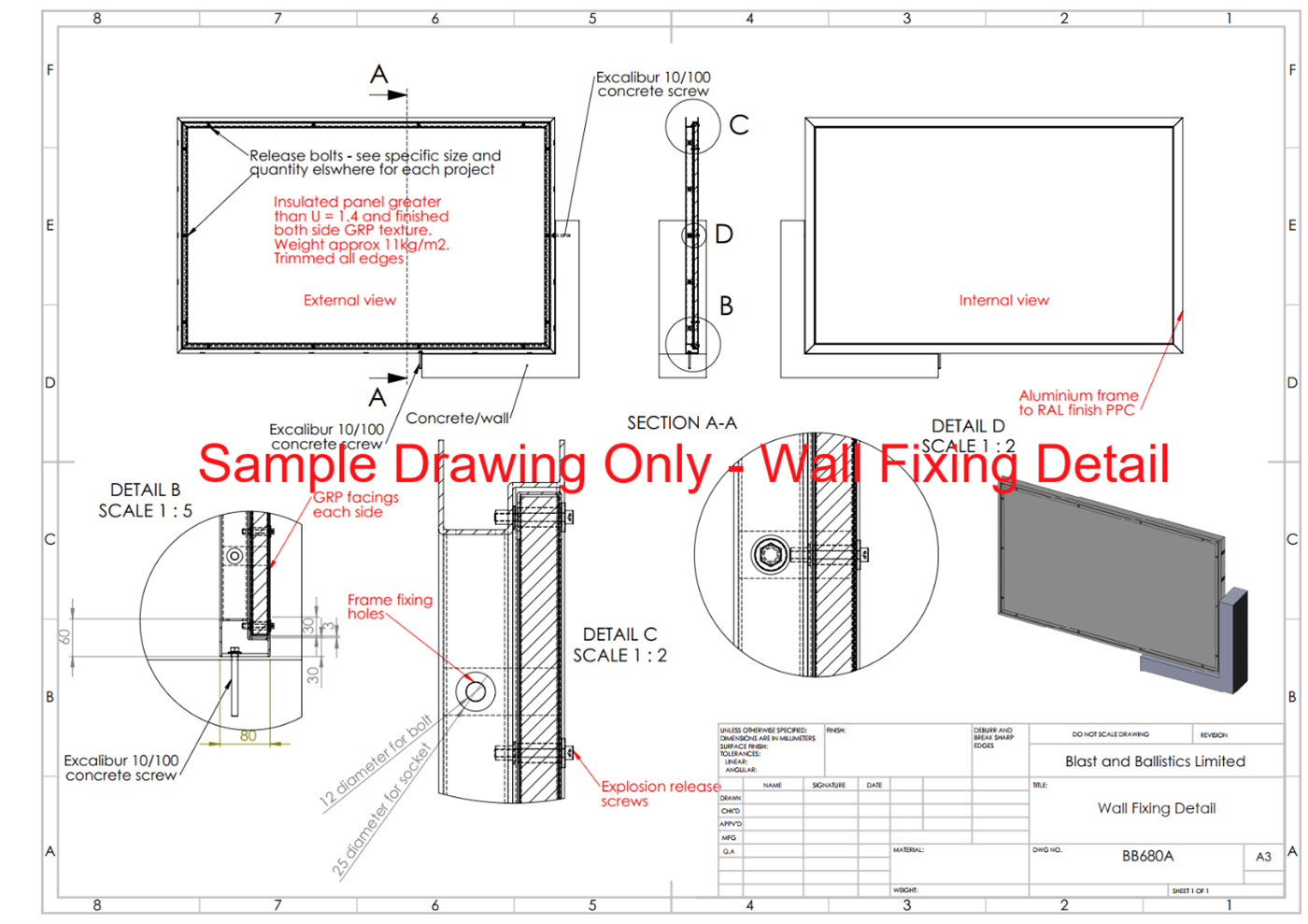

The Frangible Blow Out Panel is constructed of a stainless steel frame which fixes into the building aperture and contained within that is the Super Lightweight Insulated Frangible Panel, finished both sides with GRP to a specified RAL colour. The outer stainless steel frame is factory PPC finished again to a specified RAL colour.

Features

- All units are made to customer’s required dimensions and various wall constructions

- The product uses FM Approved Blast Release Bolts to provide accurate release values and reduce the likelihood of an incorrect release.

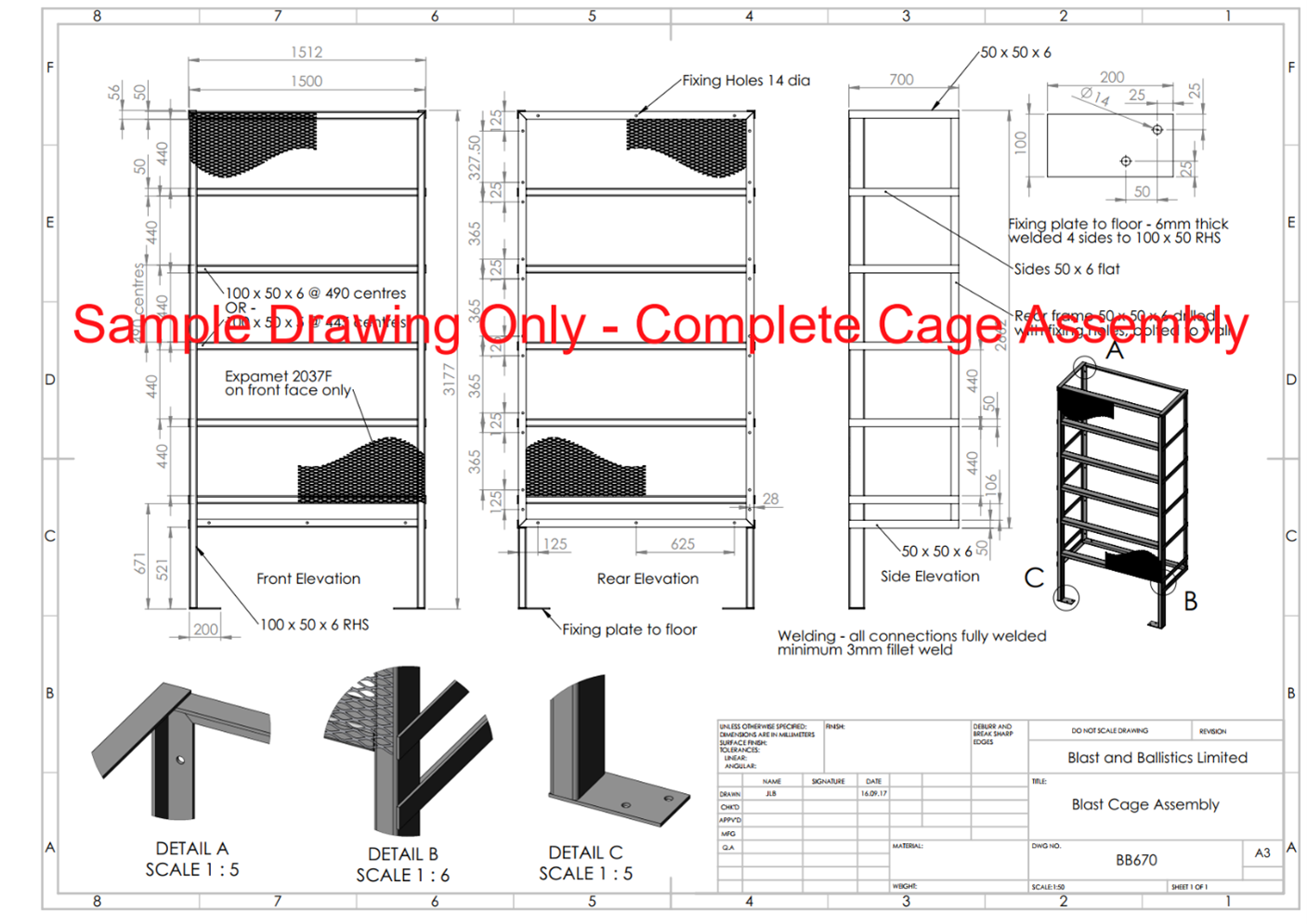

- Blast cages are available to contain the frangible panel after an event and allows blast pressure to be released sidewards and upwards.

Specification

| PROFILE |

|---|

| Available in Aluminium and Stainless Steel |

| Minimum frame depth/wall thickness 80mm |

| FINISHES |

|---|

| Factory applied Polyester Powder Coat in standard RAL colours |

| Special finishes available on request |

| AVAILABLE SIZES |

|---|

| Minimum 500mm x 500mm |

| Maximum up to 1250mm x 2400mm |

| CENTRE PANEL |

|---|

| 28mm overall centre panel thickness |

| Weighs less than 11kg/m2 |

| Insulation greater than U=1.4 |

| RELEASE VALUES |

|---|

| To suit customer specification |

| OPTIONS |

|---|

| Thermally broken Fire Rated panel |

| Extended fixing lugs if required |

| Can be installed into steel or masonry apertures |

| SHIPPING |

|---|

| Supplied in International Shipping Crates for dispatch |

Typical Areas of Application

· Chemical Production

· Petroleum Industry

· Paint, Varnish Manufacturers

· Energy/ Mining Industry

· Co-Generation Plants

· Recycling Centres

· Sewage Treatment (by-product recycling)

· Automotive (air bag, mfg. Plant lines)

· Grinding/Pulverizing processes (airborne dusts)

· Ink Manufacturers

· Energy Storage Systems (ESS)

· Industrial Processing Equipment

· Paper Process (solvent use/storage)

· Laboratory Test Facilities

· Hospitals (gas and/or flammable storage areas)

· Brewery Facilities (grain storage/processing)

· Fossil Fuel Plants (coal dusts)

· Food Processing (airborne dust)

· University Labs (chemical lab store rooms)

· Grain Milling Facilities (airborne dusts)

· Nuclear Power Stations

· Printing Companies (solvent use/storage)

· Gas/Vapour Handling Equipment

· Dust Collection Systems

Sample Drawings

Additional Information

FM Global Property Loss Prevention Data Sheets 1-44, Extract with reference to FM Approved Release Fasteners

2.1.3 Location

2.1.3.1 Locate rooms or buildings requiring damage-limiting construction in accordance with Section 3.1.1.

2.1.3.2 Avoid venting a single end of an elongated enclosure. Where this situation is unavoidable, follow the guidelines in Section 3.1.7.

2.1.4 Pressure Relieving Vent Panels

Install at least a total area of pressure relieving vent panels that equals the minimum recommended vent area.

Do not credit roof vent panel areas subject to accumulation of snow, ponded water, dust, or debris.

Where this situation is unavoidable, refer to Section 3.1.2. A maximum weight of 3lb/ft2 (14.6kg/m2) is generally recommended for venting roof panels.

2.1.4.1 FM Approved Products

Follow the manufacturer’s instructions for the installation of FM Approved (see Appendix A for definition) explosion venting systems, including fasteners and washers.

The following recommendations apply to the installation of FM Approved explosion venting systems including fasteners and washers:

1.When FM Approved, collapsing washers are used, a 1⁄2in. (13mm) diameter oversized hole should be drilled in the wall panel and a slightly smaller diameter centering washer or sleeve should be installed. It is imperative that the pilot hole for the screw/bolt be centred with respect to the centering washer. Only a specifically FM Approved No.14 (1⁄4in., 6mm in diameter) screw/bolt should be used with this washer (seeFigure2.1.4.1-1).

©2000-2023 Factory Mutual Insurance Company. All rights reserved.

Notes:

Vent-All FM Certified Approved Release Washers identification colours –

EXA-74 Colour Code GREEN Release Value Per Fastener 70# / 0.31 kN

EXA-76 Colour Code BLUE Release Value Per Fastener 110# / 0.49 kN

EXA-79 Colour Code TAN Release Value Per Fastener 175# / 0.78 kN

EXA-84 Colour Code LIGHT GREEN Release Value Per Fastener 435# / 1.93 kN

Release calculations of venting panel in this product include the weight of the roof panel e.g. –

Weight of roof panel in kN + 2 x Vent Washer in kN /vent area

The illustrated Release Washer in this Data Sheet is GREEN, release value 70lbs/0.31kN

The Release Assemblies are fitted centrally and opposing to balance the resistance of the Roof Panel

Applications that require 4 No. Release Assemblies are also paired about centre

Imbalanced blast waves can cause distortion and compromise operation. Keep Roof Panels clear of debris and snow accumulation at all times. An excessive internal explosion could compromise the restraint cables and also distort the roof panel requiring replacement before future use.

See Terms and Conditions, available upon request.

Frequently Asked Questions

How are the units installed?

We offer a full installation service if required.

Whilst we are a UK-based company, we can also provide installation overseas if required.

Installation instructions are also supplied and the units can be easily installed if the customer wishes to do this themselves.

What release pressures can be accomodated with this product?

Each application is unique and we can accomodate almost any release pressure, which is entirely decided by the customer.

We use a combination of FM Approved Blast Release Bolts which when selected appropriately, can achieve a release pressure of the customer's choosing.

Whilst a typical application may require a release value of 1kPa - 3kPa, it will vary greatly depending on the threat, location of the blast and quantity of units required.

What happens after an explosion or blast?

After an explosion or blast, the FM Approved Blast Release Bolts release the frangible panel which is then ejected outwards.

Ideally, the area behind the frangible panel where it will be dispersed into will be free of pedestrians, equipment or any other hazards.

We can also provide Blast Cages to contain the frangible panel after an event if the space in which it would be released into is not free from pedestrians, equipment, etc.