Specialist Rocket Testing Facilities

Specialist Rocket Testing Facilities and Equipment

Blast and Ballistics Limited are pleased to introduce their new range of Indoor Rocket Test Facilities.

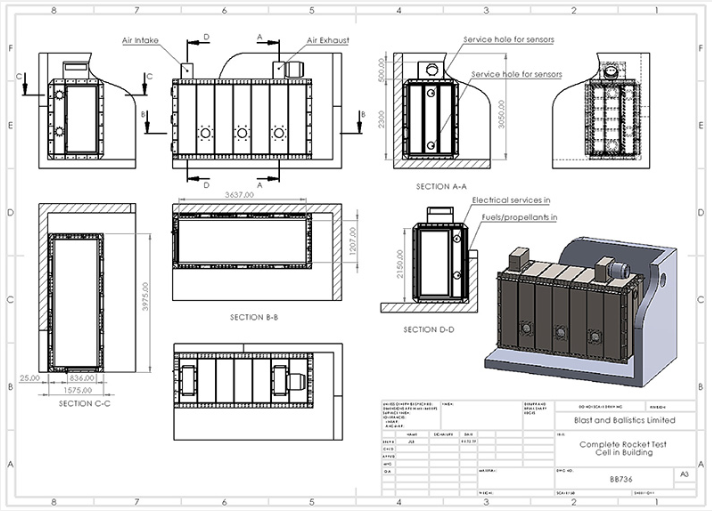

Having been approached by Dr. Peter Shaw – Senior Lecturer in Astronautics at Kingston University London, we designed, manufactured and installed an Indoor Rocket Test Facility to allow the safe firing of Rocket Motors in the region of 1-2kN and at the same time allowing the University to measure and collect data from their test programmes.

The test facility also includes a plethora of sensors to enable the University to measure temperature, pressure, gases and includes cctv cameras both internally and externally through the ballistically glazed side viewing porthole windows.

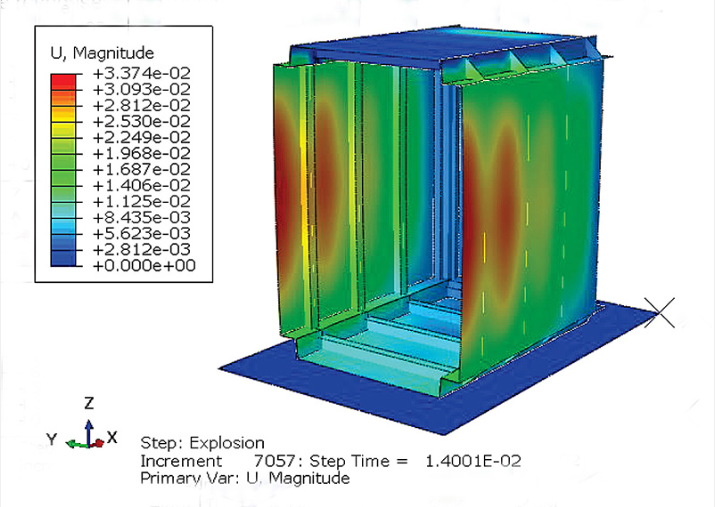

The unit is designed to contain blast pressure and fragmentation should a rocket motor fail whilst under test.

Design and Analysis

Factory Construction

Internal Finishes

Kingston University London - Propulsion Test Chamber

Kingston Rocket Lab: The ‘Rocket Lab’ within the School of Engineering and Computing at Kingston University London has a hybrid and bi-propellant rocket test facility for research into rocket engine design and can provide a range of high quality evaluation and data analysis options.

Kingston University London is divided into five faculties with each faculty offering undergraduate and postgraduate courses. The University’s Space interests are encompassed within the Faculty of Science, Engineering and Computing (SEC) which was formed in 2011 to bring together the interdisciplinary research from eight Schools, encouraging partnerships between academia and commerce.

Kingston University London has an excellent suite of space facilities that are being developed and/or are currently online for launcher and in-space propulsion related research and development. The team is happy to work collaboratively with external academics and commercial users. Our current facilities include;

- An indoor hybrid and bipropellant propulsion test facility

- An 8m catapult micro-gravity drop tower

- A machine learning propulsion laboratory

Future facilities Kingston University London hope to develop over the next five year

- An electric propulsion vacuum test facility

- A Tx/Rx (transmit and receive) satellite ground station (currently we only have a receive functionality)

- A cleanroom for space flight assembly

- A vibration table for launch and flight environmental testing

Current facilities will be available for bookings from September 2020 as they are undergoing refurbishment work presently.

Kingston Rocket Lab

The ‘Rocket Lab’ within the SEC has hybrid and bi-propellant rocket test facilities for research into rocket engine design and can provide a range of high quality evaluation and data analysis options.

The indoor propulsion test facility within the School of Engineering and Computing has a hybrid and bipropellant rocket test facility. The facility is used for propulsion testing of systems up to the low kN trust range and can provide a range of high-quality evaluation and data analysis options.

The Kingston University London indoor propulsion test facility is an indoor test chamber that allows for the testing and research of small to medium sized propulsion systems (up to low kN thrust levels). The facility can withstand a 120g TNT equivalent blast due to an accident whilst firing a system with an overpressure of 2 psi, whilst an extraction system is removing around 1.25m3 of air a second.

The facility has been designed to operate propulsion systems that operate with a maximum pressure of 70BarA. Current approved oxidizers and/or flammable propellants, with maximum flowrates (as dictated by insurance purposes) include:

- Oxygen – 83g/s

- Butane – 20g/s

- Propane – 23g/s

- Nitrous Oxide – Currently no limit

A safety report to add additional oxidizers or flammable propellants to the approved list is available at extra cost.

Restriction on propellants are based on the by-products produced and are reviewed on a case by case basis. Generally, carbon dioxide, water and carbon monoxide are currently acceptable by-products.

Additionally, there is:

- A 300 BarA rated pressure vessel for high pressure testing of small components.

- A high-end Data Acquisition (DAQ) system developed by Airborne Engineering.

- A test stand rated to 3kN but can measure between a range of 50N to 2kN.

- Please get in touch for a complete system description for this facility.

Data Analysis

In collaboration with the Kingston University London Department of Computing, experimental data from any firing tests you conduct can be analysed using developed neural networking and deep learning algorithms for deeper understanding and analysis.

In collaboration with the Kingston University London Department of Computing, experimental data from any firing tests you conduct can be analysed using developed neural networking and deep learning algorithms for deeper understanding and analysis. Using the Kingston University London High Performance Computer Cluster and GPU farm, analysis can also be done on gathered data to help optimise your system and create a prediction tool that can be used for future system modelling.

Collaboration

Kingston University London is happy to collaborate with other Universities, Industries and Institutes in their propulsion testing needs. Please do get in contact via email or over the phone to discuss opportunities further.

Student Discount

We aim to help Undergraduate students from other Universities with their final year projects as best as we can, charging minimal costs for use of our facility.

A video, taken in March 2020, post facility chamber installation but before the electrics were added, explains some of the other features available.

Contact Name

Dr Peter Shaw

Contact email address

p.shaw@kingston.ac.uk

Kingston University London

Frequently Asked Questions

What is an indoor rocket test facility?

An indoor rocket test facility is a purpose-built, blast-contained test cell that allows rocket motors to be fired safely while thrust, pressure and other parameters are measured. The ASTRO Rocket Laboratory test cell, designed and installed by Blast & Ballistics, enables safe firing of rocket motors in the 1–2 kN thrust range, while protecting people and equipment from blast pressure and fragmentation in the event of a motor failure.

How are blast pressure and fragmentation controlled during tests?

The chamber is engineered as a blast enclosure, designed specifically to contain blast pressure and fragmentation if a rocket motor fails during testing. The structure is rated to withstand a TNT-equivalent blast and overpressure scenario, and includes ballistically glazed side viewing portholes so engineers can monitor tests via CCTV without exposing themselves to risk. An extraction system continuously removes exhaust gases during firings.

What thrust levels, pressures and propellants can be accommodated?

The Kingston indoor propulsion test facility is designed for small to medium propulsion systems up to the low-kN thrust range and can operate systems with chamber pressures up to 70 BarA. Current approved oxidisers and fuels (subject to safety review and insurance limits) include oxygen, butane, propane and nitrous oxide, with defined maximum flow rates. Additional propellants can be considered via a formal safety assessment.

What instrumentation and data acquisition are available in the rocket test cell?

The test facility includes a comprehensive suite of sensors to measure temperature, pressure and gas composition, plus CCTV cameras inside the chamber and through ballistically glazed viewing windows. A high-end data acquisition (DAQ) system captures thrust and other high-speed signals (with a test stand rated up to 3 kN), and data can be processed using neural networking and deep-learning algorithms on Kingston University’s high-performance computing cluster for deeper analysis and optimisation of propulsion systems.

Who are these rocket testing facilities aimed at?

These facilities are ideal for universities, research organisations and aerospace companies working on hybrid and bipropellant rocket engines in the low-kN thrust range. The Kingston Rocket Lab specifically supports launcher and in-space propulsion research, and is open to collaboration with external academics, industry partners and students who need a safe, professionally engineered environment for propulsion testing and data evaluation.