Security Windows And Glass

Blast and Ballistics Profile 1 Heavy Duty / Security Secondary Glazing System

· A heavy duty fixed frame unit which provides blast protection to C25 (100kgs @ 25m) and forced entry to levels SR1 and SR2.

· The frame can be shaped or curved to a full circle

· 20mm glass edge cover

· Concealed room side fixing channel

· Rectangular frames may be linked with a colour matched aluminium transom section

· Standard colour semi gloss white

· All standard RAL colours PPC and woodgrain/anodised also available to customer specification

Gazing Options:

Glass: 6mm thick – 12.04mm thick

Frames: Curved head, jamb or full circle – minimum radius of 500mm

Dimensions:

Maximum Recommended Frame sizes:

Fixed Pane 2000mm wide x 3000mm high

Minimum dimensions – 300mm wide x 300mm high

Products for all levels of protection to recognised standards

New materials bring new possibilities into the areas of physical protection. As an example, lock protection and in particular cylinder protection has moved forwards to meet the continued rise in cylinder ‘bumping’, lock picking and lock snapping. Manufacturers have responded well to this challenge especially in the areas of Europrofile cylinders which are commonly used throughout many residential and commercial properties. In addition, multi point locking is now more common place than ever for this level of security.

However, whether it is window locking or door locking that may be required, it is of little use if the door or window itself is not fit for purpose. In addition to our range of standard door and window products we also meet our customer’s requirements with bespoke solutions.

Some modern materials have multi disciplined properties either by design or sometimes by default. We use materials covering a wide range of attack tools and machines as well as also being able to resist ballistic and blast attack. This opens up many possibilities in the design not only of walls, doors and windows but also other building materials and applications. Alloy steels, resins and other man made materials can all be combined to meet specific needs and threats.

Governments around the world have their own test methods and standards and in addition to that there are several commercial bodies that offer other recognised attack standards. Blast and Ballistics Ltd. have worked closely in both of these fields and have a deep knowledge and understanding of modern tools, equipment and attack methods which are employed at the highest levels of physical attack.

Surreptitious attack methods are also a closely guarded secret. They are often used at the very highest levels of Government protection where the theft of information rather than property is the major consideration. Walls, doors and windows can be probed by agencies who leave no trace of their intrusion which leaves them free to repeat their actions almost at will in some instances. We are able to provide specialist physical security products to combat these threats and we have many years of experience in doing so.

Drop Testing

10mm Tempered Glass

When hit by the falling ball, the tempered glass completely shattered, with fragments scattering and producing glass shards sharp enough to cause personal injuries.

10mm Laminated Glass

The falling ball penetrated the laminated glass creating a hole. The surrounding glass structure softened and could be easily broken into.

Typical EN356 Approved Glass Unit

The falling ball only broke the outer surface of the glass and the rigidity of the integral structure remained sufficiently strong to prevent criminals from intruding.

Guide to Security Standards for Ballistic and Manual Attack Resistance of Staff Protection Screens

BS EN 356 provides test methods and classification for resistance of glazing against manual attack. No standard exists for the testing and classification of structures containing glass resistant to manual attack. It is recommended that the complete glazed structures should be tested in accordance with BS EN 356 energy levels with pass rates one level lower (i.e. the structure for glass certified Class P5A should be tested to Class P4A energy levels) to verify that the impact does not dislodge the glass.

Testing Methods

EN 356: 1999 Classifications

1. Hard body drop test

4.11 kg steel sphere (100mm diameter)

| P1A 3 times from 1.5m | Glass thickness 6.8mm | Weight 16kg/m² |

|---|---|---|

| P2A 3 times from 3m | Glass thickness 6.8mm | Weight 16kg/m² |

| P3A 3 times from 6m | Glass thickness 9.2mm | Weight 21kg/m² |

| P4A 3 times from 9m | Glass thickness 9.5mm | Weight 21kg/m² |

| P5A 9 times from 9m | Glass thickness 10.3mm | Weight 22kg/m² |

Axe test

Impact from hammer followed by axe

Minimum no. of strikes to create opening

| P6B 30 - 50 strikes | Glass thickness 11mm | Weight 23kg/m² |

|---|---|---|

| P7B 51 - 70 strikes | Glass thickness 14.5mm | Weight 28kg/m² |

| P8B over 70 strike | Glass thickness 16.5mm | Weight 30kg/m² |

Options

• Available as DGU

• Available in shaped details

• Available in Fire Resistance glazing

• Available as privacy glass

• EN 12600 Impact Rating

• EN 356 Security Rating

• LP 1270 Security Rating

• EN 1063 Ballistic Rating

• ISO 16933 Blast Rating

• Laminate Only

• Multi Directional for Safety, Security or Ballistic

Laboratory controlled axe test on glazing unit

Typical applications for EN356 tested glazing products:

• Residential applications for burglary resistance and referenced by ‘Secure by Design’ including PAS 23 and 24

• Jewellery industry – premises, shopfronts, jewellery cabinets and showcases

• High street shopfronts

We supply EN356 glazing – also see further manufacturers data sheets at

http://uk.saint-gobain-glass.com/product/796/sgg-stadip-protect

Conventional glazing offers little protection against physical attack as shown above

EN 356 glass/PVB and glass/polycarbonate products are suitable for display cabinets and also large shopfronts in addition to domestic applications

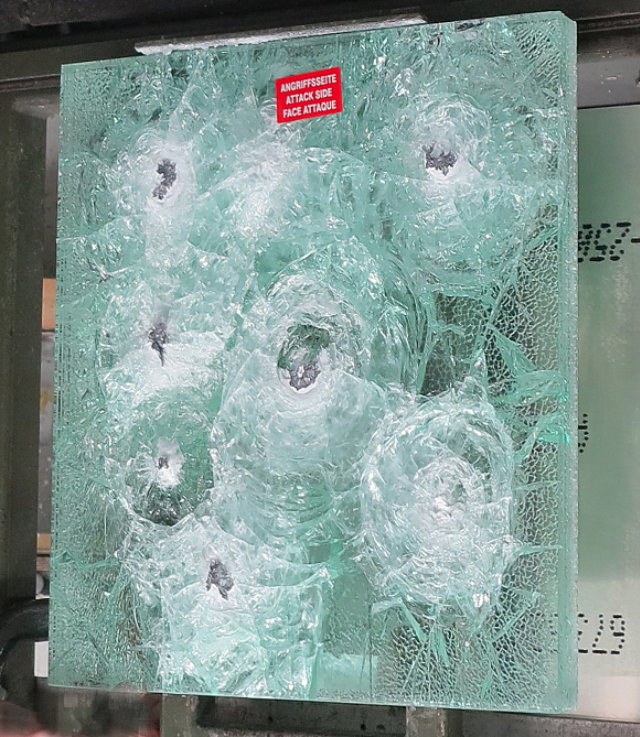

Ballistic and Bullet Glass to EN1063 BR3, BR4, BR5, BR6, BR7, UL 752 Levels 3 to 9 and NIJ 0108.01 IIIA to IV

Ballistic glass to EN1063 is constructed similarly to EN356 glass. However, due to the nature of its expectations it is usually much thicker. There are still ‘all glass’ and ‘glass-polycarbonate’ options but it is important to remember that ballistic glass is NOT designed to resist physical attack (despite its thickness) and physical attack glass is not designed to resist ballistic attack (despite its construction).

When ballistic or bullet glass is tested, it has to undergo a varying number of shots under controlled conditions. The number of shots and the spacing of the shots is dependent upon the test classification. For instance, in general terms, BS EN1063 testing requires 3 shots at 120mm spacing but an NIJ IV test would require only 1 shot. Further, EN 1063 European testing requires angle shots when the glazing unit is installed in a frame system (still attempting to find areas of weakness) whereas NIJ or UL 752 ballistic testing requires only ‘straight on’ shots.

It is also very important to remember that approved and certified glazing is only as good as the frame system that supports it. Therefore it is always important to ensure that a tested ballistic or bullet system is considered rather than simply installing an approved glass into someone else’s framing. See our Data Sheets TDSBB1005 and TDSBB1006 and TDSBB1007 for further information and details of compatible glass and framing systems.

Independent testing

United Kingdom Ministry of Defence approved test centres

Glass – Polycarbonate Ballistic/Bullet Glass

This is a combination of glass and polycarbonate. The polycarbonate layer is bonded to the inside face of the bullet glass and that prevents the inner glass layers from breaking away and creating ‘spall’. This combination of glass and polycarbonate creates a lighter weight product and at the same time reduces the overall thickness of the bullet glazing.

A comparative example would be between an all glass BR6 Non Spall glass (approximately 71mm thick) and a glass polycarbonate construction which again to BR6 would be around 38mm thick.

The consideration when using glass polycarbonate ballistic glazing is that the polycarbonate on the inside face can become scratched and fogged generally through overzealous cleaning, particularly with abrasive cleaning products. The suggested method of cleaning polycarbonate surfaces is usually water with special attention to any additives that may be suggested by specialist cleaning product manufacturers.

Spall allowed glass is a good alternative and using the above as an example then the BR6 Spall Allowed glass is 50mm thick and falls in between the BR6 NS and BR6 glass polycarbonate bullet glass. As with the BR6 NS ballistic glass it has a glass surface on both the attack side and also the protected side and therefore presents no problems when cleaning. The only time that real consideration may need to be given to Spall Allowed bullet glass is perhaps if it is used as a counter screen where the persons face is normally within around 450mm of the glass.

Glass Polycarbonate BS EN 1063 Product Details

| BR4 – 24mm thick | Weight 52kg/m² | Handgun |

|---|---|---|

| BR5 – 35mm thick | Weight 66kg/m² | Rifle |

| BR6 – 38mm thick | Weight 83kg/m² | Rifle |

| BR7 – 74mm thick | Weight 170kg/m² | Rifle |

| SG1 – 24mm thick | Weight 52kg/m² | Shotgun |

| SG2 – 38mm thick | Weight 83kg/m² | Shotgun |

Our glass is tested to:

BS EN 1063

NIJ 0108.01

UL 752 test guidelines

Email: sales@blastandballistics.com

Shown here – an all glass unit having been tested with 8 rounds of NIJ IIIA .44 caliber. Test standard is only 5 shots grouped as shown below but here we are testing over and above the test standard.

showing the 5 shot group testing of NIJ 0108.01 NIJ IIIA .44 caliber

All Glass Construction – weights and thicknesses for ballistic and blast protection glass

BS EN1063 Glass Chart

| Category | Classification | Variant | Thickness (mm) | Weight (kg/m2) |

|---|---|---|---|---|

| Bullet | BR1 | s | 13 | 32 |

| Bullet | BR2 | s | 22 | 49 |

| Bullet | BR3 | s | 23 | 54 |

| Bullet | BR4 | s | 32 | 75 |

| Bullet | BR5 | s | 36 | 84 |

| Bullet | BR6 | s | 50 | 117 |

| Bullet | BR7 | s | 85 | 206 |

| Bullet | BR2 | NS | 31 | 73 |

| Bullet | BR3 | NS | 44 | 104 |

| Bullet | BR4 | NS | 54 | 129 |

| Bullet | BR5 | NS | 58 | 139 |

| Bullet | BR6 | NS | 73 | 175 |

| Bullet | BR7 | NS | 81 | 196 |

| Blast | ER1 | S | 10 | 22 |

| Blast | ER2 | S | 18 | 40 |

| Blast | ER3 | S | 31 | 73 |

| Blast | ER4 | S | 27 | 68 |

| Blast | ER1 | NS | 18 | 40 |

| Blast | ER2 | NS | 26 | 63 |

| Blast | ER3 | NS | 33 | 83 |

References: S = Spall – small particles of the inner glass surface are allowed to fall from the back of the glass when tested and touch the witness card

NS = Non Spall – no particles of glass fall from the back of the test piece and touch the witness card

We offer glazing to protect to the following independently tested standards:

- BS EN1522/23 and EN 1063 - FB7/BR7 – 7.62 Armour Piercing Ammunition - Rifles

- BS EN1522/23 and EN 1063 - FB6/BR6 – 7.62 NATO ammunition - Rifles

- BS EN1522/23 and EN 1063 - FB5/BR5 – 5.56 NATO ammunition - Rifles

- BS EN1522/23 and EN 1063 - FB4/BR4 - .44 Magnum Handguns

- BS EN1522/23/1063 - FB3/BR3 – Handguns .44 Handguns

- NIJ 0108.01 IV - 7.62 Armour Piercing Ammunition - Rifles

- NIJ 0108.01 IIIA - .44 and 9mm Ammunition - Handguns

- UL752 Level 9 - 7.62 Armour Piercing Ammunition - Rifles

- UL752 Level 5 - 7.62 Ammunition - Rifles

- UL752 Level 3 - .44 Magnum handguns

- AK47 Kalashnikov Assault Rifles